By Mark Golden

Whether painting in oils, acrylics or other traditional or non-traditional painting media, the quality and physical make-up of the support and its preparation is a critical determinant of the final outcome of a work of art. The support not only sets up the working properties of the chosen media but it also has a significant role in its relative permanency, method of display and most importantly, in the final visual aesthetic of the work.

There are so many different viable supports for artists to work with now, including traditional cotton and linen canvases in a range of sizes, thicknesses and finish as well as newer synthetic polyester fabrics. More recent plastic supports include Mylar® (PET) and solid supports include expanded PVC (Sintra®). New solid supports gaining some significance include aluminum surfaced panels. There has also been a resurgence of new manufacturers launching a variety of traditional wooden panel supports including wood fiber processed boards. Added to this wide range of options are even larger categories of fine art papers, paper supports and now, prepared canvases and surfaces available to the artist.

More than ever before, artists have access to an amazing assortment of both traditional, modern and cutting edge sizes and grounds. This gives them the opportunity for application on everything from 4th century BC encaustics and 14th century silver point to grounds for digital printing on just about any surface imaginable. Artists can choose grounds for their specific medium as well as for adjusting the parameters of surface texture, absorbency, gloss, color, hardness and transparency.

Being given all these choices for some artists creates incredible expressive freedom, but in other ways, can be absolutely paralyzing. Having too many choices can leave one feeling overly exposed and fearful of choosing the wrong material for their particular need, leading to potential disappointment, buyer’s remorse and worse… failure.

The next several issues of Just Paint will feature articles detailing various supports and their preparation for painting. The series will begin with the most common supports and continue through the range of materials recommended for professional artists to begin the construction of their work.

Construction of the Cotton Fiber

Construction of the Cotton Fiber

The cotton fiber is made up of over 90% cellulose (and hemicellulose), water, pectins, wax, glucose and mineral salts (potassium malate). The quality and strength of the cotton fiber come from the large cellulose polymer made with upwards of 6,000 repeating glucose molecules. The natural cotton fiber is the purest made up of cellulose.

Cotton fibers are made up of areas constructed of well-ordered crystalline segments and less ordered segments or amorphous areas. The crystalline regions are tightly packed, reducing the penetration of water and other chemicals making the fibers stronger and more resistant to chemical and biological attack. The amorphous areas allow for flexibility of the fiber, but are more prone to chemical and biological degradation as well as greater absorption of water. The greater the ratio of amorphous regions of a fiber compared to its crystalline regions, the more easily the fiber is degraded. Cotton fibers contain approximately 70% crystalline regions versus linen which has up to 90% crystalline makeup of its fiber.

Cotton can be degraded by several forces including photochemical (UV and visible light), chemical attack, mechanical stress and biological attack. Effects of light will increase with increasing moisture and other photo-reactive materials in the cotton. The degradation caused by light in combination with other environmental factors produces a loss of tensile strength, increased yellowing and loss of elongation percentage, creating a more brittle textile. For artists, most canvas is protected from significant UV damage by the filtering of window glass. Damage to cotton canvas is more often the result of chemical attack from acids, enzymes from mold and mildew and most importantly, the effects of mechanical stress. Weakened canvas is more easily degraded as the damaged sites create greater permeability and are more easily degraded by these enzymes.

Cotton is highly degraded by acids or acid salts. The large cellulose polymer is broken apart and is oxidized to oxycellulose. It has long been a practice for artists to protect the cotton fabric before painting with oils with a sizing to prevent the acids in the oil and the drying catalysts from reaching the fiber surfaces. The alkaline chemistry is much less destructive to the cellulose molecule and requires much higher concentration than that found in the acrylic medium.

One of the most common destructive processes affecting cotton comes from mold and mildew growing on fabric exposed to high levels of moisture or humidity or from paintings exposed to flooding. The enzymes produced by these organisms break down the cellulose and more easily reproduce in highly moist conditions. They preferentially attack starches, potentially added to fibers either in the weaving or finishing processes. All of these conditions affecting the cotton fiber are exacerbated when the fibers are under the stresses of the woven and stretched cloth. We’ll cover the effects of mechanical stress later in this paper.

Cotton is capable of absorbing up to 25 times its weight in water. This water-loving (hydrophilic) nature is based on the strong attraction of the OH portion of the cellulose and especially the hemicellulose polymer to the water molecule. This is also the reason that unrestrained cotton fabric, when wet, will shrink dramatically as the fibers swell. Cotton canvas which is under strain, stretched, reacts slightly different. In this case the fibers also swell, but water also lubricates the fibers (in the amorphous region) allowing them to slip past one another thereby reducing some of the stress and first loosening the fabric, before dramatically retightening.

Weaving the Cotton Canvas

The weaving process for textiles requires first, a setting of lengthwise yarns that are held in tension by a loom. The word for these fibers, warp, is derived from the old English word weorpan (or Dutch werpen), meaning ‘that which is thrown across like a net’. The fill yarn that is actually woven in and out of the warp fibers is called the weave or weft (old English ‘wefen’ meaning to weave). To achieve the speed necessary in the weaving process, the use of a size, specifically in single plied yarn, is required. The size is simply a coating of material that when dry, increases the fibers’ strength and binds the surface of the fiber to reduce fraying and friction during weaving. The process of applying size to the surface of the cotton fibers is called ‘cotton slashing’. It was typical of traditional weaving processes to apply a starch to the warp fibers, which stiffens the fiber, making it less flexible. The weft fiber is not sized as it had the potential of making the fiber too brittle. The size composition for cotton typically contains corn starch, but may also be blended with other starches, including potato, wheat, rice, sago (from a variety of palm tree) or tapioca. The starches are heated with water to reduce their viscosity and make them more active. Additionally, softeners need to be added to this size to increase the pliability of the yarn and allow it a bit more lubricity for the weaving. Normal sizing is done to improve the properties of the weave. At the end of the slashing process, the fibers are dried. After the weaving, the size is typically removed. Raw cotton canvas contains significant quantities of impurities, many of which have been shown to be responsible for Support Induced Discoloration (SID) which causes significant yellowing of waterborne polymers when applied in thick layers to these fabrics. (See A Remarkable Way to Stretch Canvases (Just Paint #17) & Defining the Acrylic Patina (Just Paint #23)

The weaving process for textiles requires first, a setting of lengthwise yarns that are held in tension by a loom. The word for these fibers, warp, is derived from the old English word weorpan (or Dutch werpen), meaning ‘that which is thrown across like a net’. The fill yarn that is actually woven in and out of the warp fibers is called the weave or weft (old English ‘wefen’ meaning to weave). To achieve the speed necessary in the weaving process, the use of a size, specifically in single plied yarn, is required. The size is simply a coating of material that when dry, increases the fibers’ strength and binds the surface of the fiber to reduce fraying and friction during weaving. The process of applying size to the surface of the cotton fibers is called ‘cotton slashing’. It was typical of traditional weaving processes to apply a starch to the warp fibers, which stiffens the fiber, making it less flexible. The weft fiber is not sized as it had the potential of making the fiber too brittle. The size composition for cotton typically contains corn starch, but may also be blended with other starches, including potato, wheat, rice, sago (from a variety of palm tree) or tapioca. The starches are heated with water to reduce their viscosity and make them more active. Additionally, softeners need to be added to this size to increase the pliability of the yarn and allow it a bit more lubricity for the weaving. Normal sizing is done to improve the properties of the weave. At the end of the slashing process, the fibers are dried. After the weaving, the size is typically removed. Raw cotton canvas contains significant quantities of impurities, many of which have been shown to be responsible for Support Induced Discoloration (SID) which causes significant yellowing of waterborne polymers when applied in thick layers to these fabrics. (See A Remarkable Way to Stretch Canvases (Just Paint #17) & Defining the Acrylic Patina (Just Paint #23)

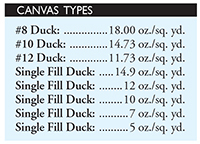

It is becoming more common for artists to use single filled (single ply) cotton for their work. The heavier single filled canvases weighing over 10 oz. will often contain a double plied yarn in the warp with a single ply weft or fill yarn. Canvas 7 oz. or less will most often be single ply for both warp and weft. Cotton numbered duck for artists contains plied fibers in both the warp and weave, meaning two or more yarns twisted together to form a stronger, thicker plied yarn.

Cotton canvas or numbered duck is usually woven in a plain weave; one yarn under and over each yarn of the warp and weft. There are examples of artists’ canvas being woven in drill or twill pattern, meaning two or three fibers in the warp over two or three fibers in the weft. The warp threads are held at tension yet the fill or weaving threads run much straighter, making the warp yarns much more crimped than the weft yarns.

Multiple ply cotton duck is measured by weight per square yard of material. These weights are commonly referred to as number ducks to differentiate them from other cotton canvas or single filled canvas.

The lower number ducks increase in weight by increasing the number of plied fibers, as well as increasing the weight (or thickness) of the yarn, therefore containing more cotton per yard. A #8 duck contains 3 ply warp and 3 ply weft fibers. It is the thickest of typical artists’ canvases, making it a bit more difficult to stretch. It is commonly used for floor cloths and has a very pronounced texture. The #12 cotton duck is the most common numbered duck for artists’ use and consists of two ply yarns in both directions. A #10 cotton duck, a coarser canvas using thicker plied yarns is also a common artist canvas and is often used for larger canvases above 4 feet. It is simply a much sturdier fabric. The yarns in number duck run between 7 count (coarse) to 11 count¹. It is very common that some inexpensive canvases use fabric that is as light as 5 oz. per square yd. using a 16 count yarn and thinner. When the prepared canvas is already filled with a priming coat of a synthetic gesso it feels much more substantial. Some manufacturers of prepared canvas provide the weight of the canvas including the size and/or ground, making it difficult to know the actual weight of the raw cotton fabric. As the cotton canvas gets lighter, it tends to be a more open weave and is usually made with single filled (or non-plied yarns called single ply). Thinner fabrics may be less stable over time especially when tightened over a stretcher, given the stresses on the material to keep it taut and in-plane. The lighter canvas does have a less pronounced weave, which may be attractive to some artists. It is often sold as ‘portrait canvas’.

The tear strength and tensile strength of the numbered cotton duck is typically stronger than a similar weight single filled duck of the same quality fibers. It is possible to gain significantly greater strength of the fabric by using better quality cotton fibers and a thicker yarn in both the single and double filled canvas. In single filled cotton duck, the weight gets lighter as the yarn width gets thinner, yet it is also typical that the yarn count will increase slightly to maintain the structure. Both the tensile strength and the tear strength are greater in the warp yarns than the fill yarns. Not only are the warp and weft fibers potentially different in their width and number of plied yarns, but they will also differ in the number of twists of the yarn, with the warp usually having more twists, reducing the number of hairs protruding from the threads. It is therefore easy to understand that the fabric will have different properties of stretch and strain in the warp and weft.

The final cotton fabric is graded according to several factors; its lightness of color, the amount of trash (plant material not cleaned in the ginning or spinning process), the number of broken yarns, misweaves, oil staining, other colored yarns, slubs or neps (bumps in the canvas often caused by immature fibers, or smaller fibers getting through the yarn making process) or broken yarns. The grades of woven cotton fabrics range from AB for the poorest goods with the most amount of defects and the weakest strength to A++ grades with the fewest amount of defects and strongest goods. Cotton canvas for artists is typically A grade goods with some at the lowest AB grades. It is therefore important for artists using unprimed cotton duck to check the fabric, especially if a very smooth, continuous surface is desired. If the canvas is pre-primed it’s more difficult to recognize flaws, but most quality manufacturers of pre-primed canvas have inspected their goods for missing weave and slubs, which will show up on visual inspection of the canvas even with pre-priming.

The final cotton fabric is graded according to several factors; its lightness of color, the amount of trash (plant material not cleaned in the ginning or spinning process), the number of broken yarns, misweaves, oil staining, other colored yarns, slubs or neps (bumps in the canvas often caused by immature fibers, or smaller fibers getting through the yarn making process) or broken yarns. The grades of woven cotton fabrics range from AB for the poorest goods with the most amount of defects and the weakest strength to A++ grades with the fewest amount of defects and strongest goods. Cotton canvas for artists is typically A grade goods with some at the lowest AB grades. It is therefore important for artists using unprimed cotton duck to check the fabric, especially if a very smooth, continuous surface is desired. If the canvas is pre-primed it’s more difficult to recognize flaws, but most quality manufacturers of pre-primed canvas have inspected their goods for missing weave and slubs, which will show up on visual inspection of the canvas even with pre-priming.

Stretching Cotton Canvas

Most artists using unprimed cotton canvas will do their priming after the canvas is stretched. Whether sizing with acrylic primers, rabbit skin glues or PVA size or going directly to acrylic gesso (acrylic dispersion grounds), these materials all contain water. Water will dramatically swell the cotton threads, causing the total length of the fibers to shorten, and therefore increase the tension of the stretched fabric. In some cases, the tension created can splinter or warp the wood stretchers. Even if the stretchers are able to withstand the forces created, the differential in stretching will show itself in the variability of the tension next to the staples in a scalloped patterning. In James Bernstein’s technical paper in Just Paint 17, he shares the benefits of pre-stretching your canvas before final attachment to your support. By sizing (pre-wetting) and pre-stretching, the cotton is both allowed to come to a greater equilibrium as well as cementing or locking the fibers into a more protected composite material. Also demonstrated in the Just Paint 17 article“A Remarkable Way to Stretch Canvases” is Bernstein’s technique for stretching the perfect canvas, creating an even tension across the entire surface of a canvas.

For a description of the differences between stretchers and strainers, see the Just Paint article, “Stretchers and Strainers: Secrets of the Trade“ by David Headley, and “A Remarkable Way to Stretch Canvases“ by James Bernstein.

Sizing Canvas for Acrylic Painting

Applying a very fluid acrylic polymer to the cotton canvas either in the process of pre-stretching the duck or applying over an already stretched unprimed canvas will both lock the fibers in place, reducing the movement and vibration of the canvas. Not all acrylic sizes are equivalent in their ability to reduce the dirt, trash and water soluble components of the cotton fabric from penetrating back into the painting and potentially discoloring acrylic films. Other than washing your canvas, which is in many cases impractical, using an appropriate size will reduce the potential for SID.

Applying a very fluid acrylic polymer to the cotton canvas either in the process of pre-stretching the duck or applying over an already stretched unprimed canvas will both lock the fibers in place, reducing the movement and vibration of the canvas. Not all acrylic sizes are equivalent in their ability to reduce the dirt, trash and water soluble components of the cotton fabric from penetrating back into the painting and potentially discoloring acrylic films. Other than washing your canvas, which is in many cases impractical, using an appropriate size will reduce the potential for SID.

We have recommended using a specialty acrylic polymer, GAC 100, to block the bleed through from the canvas additives. Additionally, our Polymer Medium (Gloss) is also a very effective size capable of reducing the effects of SID in your acrylic painting. Both GAC 100 and Polymer Medium (Gloss) are very flexible under normal indoor temperatures above 50° F.

Sizing the cotton canvas with an acrylic polymer or medium that is allowed to soak through or is forced into the canvas fibers creates a composite of cotton threads and acrylic binder that dramatically reduces the overall stretch of the support, making it much more rugged, stiff and capable of reducing a great deal of the floppiness of the stretched canvas.

Most artists will go directly to applying an acrylic gesso on the unprimed canvas without a size coat. This can also effectively lock in the fibers of the cotton, reducing the elongation of the fabric. It creates a relatively hard, absorbent and toothy surface for subsequent adhesion of the acrylic paints. Multiple coats of the acrylic gesso will increase the hardness and increase the tensile strength of the composite fabric and acrylic ground. The whiteness of the gesso also gives a beautiful reflective surface that will increase the luminosity of colors above. Acrylic gesso is typically produced with titanium dioxide to improve the overall whiteness of the surface. Titanium dioxide pigment is well known as a UV blocker, reducing the damage caused from this spectrum of radiation from bombarding the cellulose structure of the cotton fibers.

Whether using first, a size, or directly applying the acrylic gesso to the canvas, the canvas can still be stretched with significantly less concern over cracking the priming layers. Acrylic gessoes do vary significantly in a number of ways, including their flexibility, but a new standard (ASTM D-7733) has been developed that requires manufacturers conforming to the standard, to produce a relatively flexible film allowing the cotton canvas to at least fold over a 90° angle without cracking. It is hoped that this new standard will be adapted by the many manufacturers of artists’ acrylic gesso.

All acrylic artist paints become less flexible in lower temperatures and quite stiff in freezing temperatures. These films are prone to cracking if hit or stretched, rolled or unrolled while frozen. Stretching or re-stretching already acrylic primed canvases should be done above 65° F.

We have found that the acrylic gessoes by themselves do not reduce the effects of SID from cotton canvas, even when multiple coats are applied. Acrylic gesso is typically filled with pigment and functional solids (calcium carbonate, silica) as well as other additives. These coatings are quite porous and allow those impurities in the cotton duck to migrate through the gesso and into the acrylic paints on the surface. The high solids of an acrylic gesso create an even more porous film allowing for significant infiltration of moisture to the cotton fibers.

Applying Size and Grounds

With the advent of acrylic, artists have been freed from so many of the restrictions required to create a stable and relatively permanent painting using other traditional painting media. But there is still an opportunity to share best practice as we currently understand it for artists working with acrylic on cotton duck.

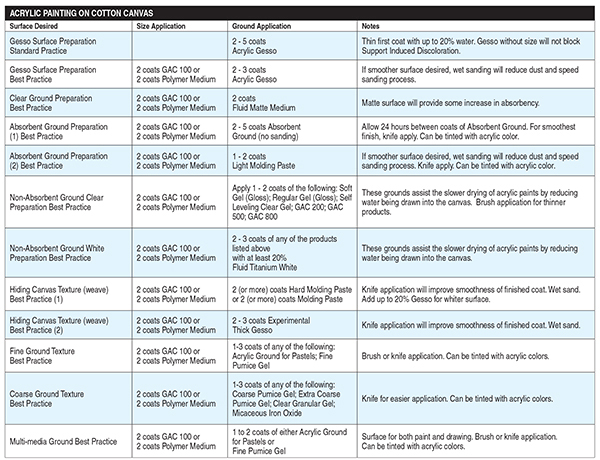

When applying a size to cotton duck we have recommended an application of a thin medium. Our Polymer Medium thinned with up to 20% water will easily soak into the cotton fibers and lock them in place. Brushing the size layer on with a stiff brush will tend to force the acrylic binder into the fabric. Some artists will use a broad painter’s blade to both size as well as apply the gesso ground. This allows for an even application, further forcing the medium into the canvas. We have recommended two coats of our Polymer Medium or GAC 100 to act as a sealer for the canvas. On top of this size coat, there are a wide range of grounds that can then be applied. The grid to the right shares the types of applications and grounds that can be possible within the acrylic medium.

Cotton Canvas Without Size or Ground

This process dates back to the early stain painting of Morris Louis, Ken Noland and Helen Frankenthaler. There is currently no coating or size that will completely mimic the way paint lays down on raw cotton duck, yet to achieve this aesthetic, the artist is sacrificing the benefits that a substantial size and ground will provide. Most artists have learned not to work with oil directly on raw cotton duck, yet even for artists working with acrylic, there is still concern that the unprotected cotton fibers lacking the restraint of a binder will be more easily abraded, degraded, collect dirt, and move.

Retaining the Look or Feel of Raw Duck

Although it is possible to achieve a very similar likeness of raw cotton duck, it is difficult to achieve both the look of the cotton fabric and its level of absorbency with the same approach.

It is possible to retain the look of the cotton by applying the two coats of Polymer Medium and then finishing with a coat of Fluid Matte Medium which will provide some of the matte quality of the fabric surface while also protecting the fibers. This will not dramatically cover the creamy color or fill in the texture of the canvas cloth.

If you wish to have some of the same absorbency as the raw cotton fibers, again it is necessary to first size with two layers of Polymer Medium or GAC 100 and then multiple coats of Absorbent Ground or our Light Molding Paste. These are very opaque coatings and will cover all of the canvas color below.

Protecting the Back of the Canvas

There are some suggestions that applying a coat of gesso or an acrylic size to the back of the canvas before stretching it may be a way to protect the canvas. This will certainly stiffen the canvas and assist in locking fibers in place, yet the jury is still out as to whether applying a porous coating on the back is the best process. It does provide some barrier protection, for example, from the leaching of acids from wooden stretcher bars into the cotton fabric as well as slowing down the movement of the cotton threads caused by changes in temperature and humidity. Too thick a coating or an uneven coating on the back of the canvas will potentially reflect itself onto the surface of the canvas.

In Just Paint 17, James Bernstein has provided a very practical approach to backing your stretched canvas. In addition, the new AIC Conservation Wiki http://www.conservation-wiki.com/wiki/Main_Page provides one of the most complete and up to date resources for best practices in conservation. This site is open to the public and is an invaluable contribution to artists wanting to understand current thinking in art conservation. Protecting the back of the fabric from large shifts in humidity, dirt, bugs and the typical damage caused by unaware helpers can be the most significant aid in protecting your work. Cotton canvas remains one of the most versatile, lightweight, and aesthetically appealing surfaces to work on. There are multiple ways to prepare fabric for a wide range of techniques and applications providing considerable longevity to your finished work.

¹Yarn thickness is measured by a long standing tradition determined by the yield length of one pound of cotton. A 1 count or size 1 yarn is one pound of cotton, creating 840 yards of thread.A size 100 yarn would yield 84,000 (extremely thin) yards of fibers. In the decimal system the constant is the gram weight of 1000 meters of cotton. Called the Tex system a 1000 meter thread. Tex 10 would weigh 10 grams and be very fine. A tex 100 would be a coarse fiber.

Bibliography

Bresee, Randall R., General Effects of Ageing on Textiles, Journal of the American Institute for Conservation, JAIC 1986, Volume 25, Number 1, Article 4, pp. 39 . 48

Claredon Textiles, Inc. Website, www.claredontextiles.com, What is the Story Behind the Yarn Count?, Copyright 2009, Claredon Textiles

Eastop, Dinah, nes T-Balsy, Chemical Principles of Textile Conservation, Butterworth Heinemann, 1998, pp. 11-34, 100-108

Frayler, John, Park Historian, Salem Maritime NHS, A Brief History of Sailcloth During the Age of Sail, Pickled Fish and Salted Provisions: Historical Musings from Salem Maritime NHS, Courtesy of the National Park Service

Gamble, Gary R., Implications of Surface Chemistry on Cotton Fiber Processing, The Journal of Cotton Science 8: 2004, pp. 198 – 204 GMO Compass, http://www.gmo-compass.org/eng/grocery_shopping/crops/161.genetically_modified_cotton.html, December, 2008

Hamilton, Donny L, 1998. Methods of Conserving Underwater Archaeological Material Culture. Conservation Files: ANTH 605, Conservation of Cultural Resources I. Nautical Archaeology Program, Texas A&M University, World Wide Web,http://nautarch.tamu.edu/CRL/conservationmanual/

Keyser, Barbara Whitney, Restraining Without Stress, History and Prospects: A Literature Review of Paintings as Structures, Journal of the American Institute for Conservation, JAIC 1984, Volume 24, Number 1, Article 1, pp. 1 . 13

Oosterhuis, Derrick, Mac Steart, Dave Guthrie, Cotton Fruit Development: The Boll, Cotton Physiology Today, Newsletter of the Cotton Physiology Education Program, National Cotton Council, Vol. 5, No. 7 August 1994

Pocobene, Gianfranco, Ian Hodkinson, Use of a Pressure-Sensitive Adhesive to Facilitate the Transfer of a Severely Tented Painting, JAIC 1992, Volume 31, Number 2, Article 2, pp. 161-173

Young, Christina, Eric Hagan, Interfacial Interaction of Modern Paint Layers, Modern Paints Uncovered, Postprints Tate/ Getty/ NGA Symposium 2006, pp. 247-256.

Resources:

http://www.cotton.org/pubs/cottoncounts/fieldtofabric/forty-frames.cfm

Follow the story of modern cotton and fabric production in pictures

http://www.cottoninc.com/product/Tech-Assistance-Training/

Photos of standard cotton fabric defects

About Mark Golden

View all posts by Mark Golden -->Subscribe

Subscribe to the newsletter today!

No related Post