By Dana Rice

You’re seated at a white clothed table in an uptown restaurant; the chef has just placed an incredible creation down in front of you. You take a bite and a complex mixture of flavors and spice awaken your palette. You can’t quite put your finger on it, but there is an ingredient that pulls the whole dish together, something added that brings out just the right flavor.

For many artists, that unique, additional ingredient for their work can be found in the line of GOLDEN products called Specialty Acrylic Polymers. Within the line, the products are identified by the letters “GAC” followed by a number. The letters “GAC” stand for Golden Artist Colors, but commonly the line of products is referred to as the “GACs” (pronounced: gaks, rhymes with yaks). The number that follows is an identifier, but does not have significance relative to any other product, or to the product’s capabilities.

The Specialty Acrylic Polymers, or GACs, are formulated based on 100% acrylic dispersion polymers with only a minimum amount of thickeners, freeze/thaw stabilizers, defoamers and preservatives. The GACs are fluid and thin, and are therefore generally considered a component to be used in conjunction with something else, rather than as a stand-alone product. Each GAC represents a unique polymer that offers certain specific attributes; therefore, each GAC will have its own unique benefits and applications. They are building blocks.

With this in mind, the GACs can be blended with GOLDEN Acrylic Paints to extend the paint, regulate transparency, create glazes, increase gloss, reduce viscosity or improve adhesion and film integrity. Since the GACs have minimal thickeners added, these polymers will reduce the thickness of most GOLDEN Acrylic Paints. GOLDEN Fluid Acrylics are slightly thicker than the GACs, but is the color line least changed in viscosity with any addition of a GAC polymer.

polymers and is useful for artists formulating their own paints.

GAC 100 is a multi-purpose acrylic polymer. GAC 100 is ideal as a sealer for protecting against Support Induced Discoloration (SID), a condition resulting from impurities that are drawn up through an unprimed substrate as the acrylic paint dries, discoloring the paint. GAC 100 is also useful for diluting and extending colors, increasing flexibility and film integrity, sizing for fabric, and sealing for wood. GAC 100 will wet out solids, including pigments, more readily than other polymers and is useful for artists formulating their own paints. GAC 100 is soft and flexible, so if the color blends get too tacky, modifying with GAC 200 will reduce the tack.Over the years, the line of GACs has been developed based on requests for different types of building blocks

containing attributes for specific applications or effects. What follows is a description of each GAC product and

its particular attributes.

Common Uses: Sizing, protection against Support Induced Discoloration (SID), linseed oil blocker, extending Heavy Body paints, paint-making with dry pigment

glass adhesion test done in the GOLDEN Lab.

GAC 200 (bottom) demonstrates its ability to

adhere to nonporous surfaces such as glass.

GAC 200 is an acrylic polymer designed for increasing film hardness. The hardest and least flexible of our polymers, GAC 200 is ideal for mixing with acrylic colors to increase film hardness and reduce dry film tack. This is particularly useful when using masking tools such as painter’s tape. The increased film hardness ensures a cleaner edge when the masking tape is removed. In addition, GAC 200 improves adhesion to non-porous surfaces; however some surfaces, such as glass and glazed tile, will not allow for a permanent bond. Due to the film hardness achievable with GAC 200, if the mixture contains more than 50% GAC 200, it is not recommended for use on flexible supports, as cracking may result. On rigid supports, a maximum of 75% GAC 200 is recommended.

Common Uses: Increase film hardness, reduce tack, masking techniques, increase adhesion on nonporous surfaces

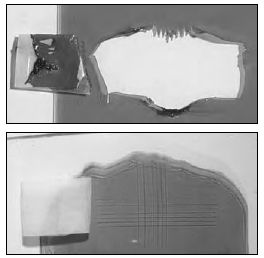

GAC 400 is an acrylic polymer designed to stiffen natural fibers, including fabric and some types of paper. Fibers saturated with GAC 400, or GAC 400 blended with color, will dry to a hard, stiff film. Lightweight fabrics, such as cotton and linen, can be molded and shaped into fixed forms.

Common Uses: Stiffen and form fabric/paper, create sculptural elements, size canvas

GAC 500, with a unique balance of film hardness and flexibility, is the hardest acrylic polymer within the product line that is still pliable enough to be used on flexible supports. GAC 500 offers increased leveling, increased mar resistance and decreased dry film tack. The increased film hardness ensures a cleaner edge when using masking techniques. GAC 500 is particularly useful for extending Fluid Acrylic colors with minimal property change. In addition, GAC 500 can be mixed with Airbrush Transparent Extender to create a fast-drying, sprayable isolation coat.

Common Uses: Decrease brush strokes, increase mar resistance, masking techniques, base product for airbrush sprayable isolation coat

GAC 700 has higher solids in the base resin formula than most other polymers (60% versus 48%). The higher solid content increases film clarity and transparency, while minimizing shrinkage. GAC 700 is useful for sealing porous materials. Relatively soft, GAC 700 blends can result in an undesirable degree of tack. Modifying the blend with GAC 200 will reduce the tack. The GAC 700 dispersion has a tendency to generate foam during application, so care should be exercised when brushing.

Common Uses: Increase transparency, seal cork

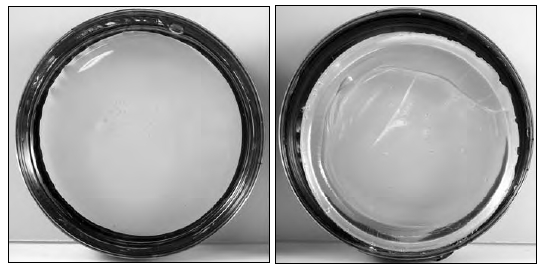

GAC 800

applications (left). As puddles dry, uneven drying rates within the layers of the pour can result in “crazing,”

shrinkage crevices that run across the surface (right).

Common Uses: Reduce crazing with puddles and pours, increase adhesion to chalky surfacesis an acrylic polymer designed to reduce crazing in puddles, pours, and other thin pourable paint applications. As puddles dry, uneven drying rates within the layers of the pour can result in “crazing,” shrinkage crevices that run across the surface. The addition of GAC 800 to the acrylic color promotes drying with a smooth, even film. In addition, GAC 800 is also useful for adhesion to chalky surfaces. GAC 800 dries with good gloss and film flexibility, but with a slight “hazy” quality. When mixing GAC 800 with color, gently stir to avoid foaming. If foaming does occur, place the mixture in an air-tight container and allow to sit for 1-2 days, until the bubbles have enough time to rise to the top and dissipate.

GAC 900 is an acrylic polymer designed for fabric and clothing applications. When heat-set properly, the addition of GAC 900 to color lends painted fabrics a very soft hand and laundering stability. GAC 900 can be mixed with Airbrush colors to produce “tie-dye” effects on pre-wetted material, or blended with GOLDEN Heavy Body, Matte or Fluid Acrylics for brush or screen application. To further promote launderability during spray

applications, GAC 900 may be used full strength as a basecoat, as well as a thin topcoat. Optionally, GAC 900 applied as a basecoat, then heat-set, will “seal” the fabric surface prior to paint applications. For thicker screen or brush applications, mix color with Silkscreen Fabric Gel, a gel product with the same soft-hand and launderability properties of the lower viscosity GAC 900.

Note: Provide adequate ventilation when heat-setting with GAC 900 as the process releases low levels of formaldehyde.

Common Uses: Soft-hand and laundering stability for painted fabric, “tie-dye” effects

About Dana Rice

View all posts by Dana Rice -->Subscribe

Subscribe to the newsletter today!

No related Post