3D prints have become a much more frequently used and a more readily available medium for artists and sculptors. Desktop 3D printers are now affordable and online 3D printing services are available in abundance. Some filaments allow for full color prints, but particularly in smaller prints, the quality of these prints can lack detail and definition. Also, who doesn’t love a little blemish, proof of the handmade, which makes for a truly individual and customized model? For many artists the question then arises – How to paint and finish 3D prints? To be honest, we weren’t sure. So, we decided to dive into the world of 3D printing, carry out our own tests, learn and share with you.

Test Materials

There are way too many proprietary materials from 3D printer vendors available, to cover them all. For our tests we focused on the most commonly used plastics and materials that we have had questions about:

- PLA (Polylactic acid)

- PETG (Glycol-modified Polyethylene Terephthalate)

- PA12 (Polyamide 12) & Alumide

- ABS (Acrylonitrile Butadiene Styrene)

- PC-ABS (Polycarbonate-ABS)

- TPU (Thermoplastic Polyurethane)

- Photopolymer Resin

- Sandstone

Most samples were printed in FDM (Fused Deposition Modelling; layer-by-layer deposition of an extruded filament through a heated nozzle), including PLA, PETG, PA12, ABS, and TPU. PA12 and Alumide were additionally also printed in SLS (Selective Laser Sintering; a laser sinters powdered plastic material into a solid structure). Photopolymer Resin samples were printed in PolyJet (printer jet drops off photopolymers that solidify when exposed to UV light). The Sandstone samples were printed with Material Jetting (inkjet print heads apply a liquid bonding agent onto thin layers of powder).

We wanted to know how well our acrylics adhere to these prints, as well as how effective some of the most common primers are in promoting adhesion. On top of that, we tested various varnishes and topcoats.

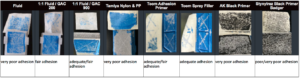

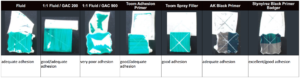

For the acrylics we chose High Flow (Sepia) and Fluid (Phthalo Green Blue Shade) paints as they produce thin paint films, which should reduce the risk of adhesion failure. GAC 200 was tested in 1:1 mixtures with Fluid. GAC 200 is our hardest acrylic medium and a harder film should be more durable on non-porous surfaces. GAC 900 was also tested in a 1:1 mixture with Fluid and after air drying, was heat-set for several minutes with a hair dryer. With the GAC 900 we hoped to improve adhesion on flexible 3D prints, such as TPU. GAC 900 is intended for fabric applications to create a softer hand of paint layers and increase launderability of wearables, thus, this application on plastics is experimental. The Tamiya Nylon & Polypropylene should promote adhesion on nylon and PP plastics, and was chosen particularly to test on PA12 (a.k.a. Nylon 12). The Toom Plastic Adhesion Primer and Toom Spray Filler are both from a local hardware store brand and comparable products would be, for example, DupliColor Plastic Primer and Rust-Oleum Filler Primer. These are products that are frequently suggested for painting 3D prints. The AK Interactive Black Primer and Stynylrez Easy App Surface Primer are products intended for priming miniatures and figurines.

Summary of Test Results

- We found that PLA and PETG were by far the easiest 3D printing materials to coat and acrylics had excellent adhesion without prior priming. PC-ABS, photopolymer resin and SLS-printed PA12 and Alumide were the runners-up. On FDM-printed PA12, ABS, and TPU adhesion of acrylics proved difficult and primers necessary. On Sandstone none of the tested coatings were successful.

- There was no noticeable difference between High Flow and Fluid paint films on any print. The addition of GAC 200 to Fluid paint improved adhesion on SLS-printed PA12 and Alumide, as well as on the photopolymer resin.

- On SLS-printed TPU the addition of GAC 900 to Fluid had the greatest impact in terms of adhesion improvement, but GAC 900 also improved adhesion on SLS-printed PA12 and Alumide.

- The Tamiya Nylon&PP Primer indeed only effectively improved adhesion on FDM-printed PA12, but not on SLS-printed PA12 or Alumide.

- The Plastic Adhesion Primer and the Spray Filler improved adhesion significantly on all critical materials.

- Between the AK Black Primer and the Stynylrez Primer, the latter performed slightly better (particularly on photopolymer resin), but generally improved adhesion only minimally, if at all.

- Archival Varnish Gloss, MSA Varnish Gloss, and ColorMatic 2K Clear Coat were tested on PLA, PETG, PA12, ABS, TPU and Sandstone. The varnishes and clear coat dried well on all materials, besides Sandstone, on which the ColorMatic 2K Clear Coat remained tacky for one day and the MSA Varnish on Sandstone was sticky for one week.

Adhesion Tests

For the adhesion tests, we followed the same technique as described in Will It Stick? Simple Adhesion Testing In Your Studio. Especially on non-porous surfaces, water-based coatings may build up adhesion over time. Therefore, we tested all coatings after 3 days of drying at room temperature. We used a classification system with six categories:

| Excellent | The edges of the cuts are completely smooth; no paint is detached. |

| Good | Small flakes of the coating are detached along the cuts; less than 5% of the area is affected. |

| Adequate | Small flakes of the coating are detached along the cuts; less than 15% of the area is affected. |

| Fair | Small flakes of the coating are detached; less than 35% of the area is affected. |

| Poor | Less than 50% of the coating is detached. |

| Very Poor | More than 50% of the coating is detached. |

1. PLA (Polylactic acid)

PLA (polylactic acid), is a biodegradable plastic produced from renewable raw materials such as corn starch or sugar cane. In ideal landfill conditions it takes about 6 months for signs of decay to occur, but at regular room temperature and normal pressure PLA lasts for many years. PLA products surround us daily in packaging materials, trays or cups. It has only moderate weather resistance but good UV-resistance. PLA is a popular choice when starting out, because it is easy to print.1

PLA proved to be a very suitable filament for painting on directly with acrylics. Both High Flow and Fluid Acrylics showed excellent adhesion.

2. PETG (Glycol-modified Polyethylene Terephthalate)

PETG is a reliable filament that produces durable prints. PET is the most widely used plastic in the world (e.g. water bottles) but only the PET variables PETG or PETT (Polyethylene coTrimethylene Terephthalate) are used for 3D printing.2

On our very thin and flexible smiley bookmark printed in PETG, we tested Fluid and a 1:1 Fluid GAC 900 mixture. Both paint films did not crack when we flexed the bookmark, but the GAC 900 mixture showed better adhesion.

On the PETG prints acrylics had excellent adhesion. Most primers slightly decreased the adhesion, particularly so the Tamiya Nylon & PP Primer.

3. Nylon/Polyamide 12 + Alumide

Polyamide (PA) 12 is the most heavy weight filament, strong, flexible and durable. Alumide is a mix of polyamide powder and fine aluminum particles.3

We found that there was a significant difference between nylon prints that were produced by SLS (selective laser sintering) versus FDM (fused deposition modeling). All coatings had better adhesion on SLS-printed nylon. Several sources on the internet suggest dying nylon for FDM printing, rather than painting it. With a dye intended for synthetic fabric, one can either dye the finished print, or the nylon filament prior to printing, but that’s something we did not test.4

The plastic adhesion primer improved adhesion best on both FDM and SLS printed Nylon and Alumide. The addition of GAC 900 (heat set) and GAC 200 to Fluid Acrylics also improved the film adhesion somewhat.

Tests on FDM printed PA12:

Tests on SLS printed PA12:

Tests on SLS printed Alumide:

4. ABS (Acrylonitrile Butadiene Styrene)

Typical ABS products are manufactured goods, e.g. Lego® bricks. ABS has good weather resistance and moderate UV-resistance. Releases odor during printing and requires printing experience.5

Our ABS print of an elephant came out pretty rough, so we tried to smooth and correct its trunk with Molding Paste and the rest of his body with Sandable Hard Gesso. The Molding Paste and Gesso went on well without beading up, but it required multiple coats to even out the structure. The Sandable Hard Gesso showed good/adequate adhesion.

Of all coating options the plastic adhesion primer performed best on ABS (third from right).

5. PC-ABS (Polycarbonate-ABS)

PC-ABS is a high-impact engineering thermoplastic used for functional prototyping and low-volume manufacturing. PC-ABS combines the superior strength and heat resistance of PC and the flexibility of ABS.6

Although, it might be a rather unusual filament for the fine arts usses, we ran a few tests and found that Fluid Acrylics had excellent adhesion to PC-ABS without primer.

6. TPU (Thermoplastic Polyurethane)

TPU is one of the most commonly used elastic polymers, or elastomers. It makes for prints with very high flexibility and durability. TPE is a category of rubberlike plastics and does not refer to a specific material. Due to its flexibility it is frequently used for phone cases, grippers, handles or seals and the like.2

The plastic adhesion primer performed best on the TPU test squares, followed by the spray filler.

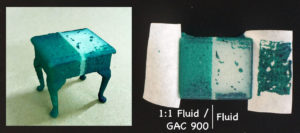

We also had a flexible table printed with TPE with the selective laser sintering (SLS) method. Half of the table we painted with Fluid Acrylics (Phthalo Green BS) and the other half with a 1:1 mixture of GAC 900 and Fluid Acrylics (with subsequent heat setting). The difference in adhesion was immense. The 1:1 mixture had excellent adhesion, while the pure Fluid layer failed completely.

7. Photopolymer Resins

Photopolymers used for 3D printing are liquid plastic resins, which are cured and hardened with light. Unlike thermoplastics (like acrylic paints or PLA, PETG, PA12, ABS, or TPU), photopolymers are thermosets, meaning that, once the chemical reaction takes place to harden the material, it cannot be remelted.7

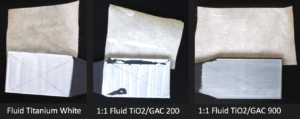

The adhesion primer, spray filler and 1:1 mixture of Fluid Acrylics and GAC 200 performed best on the resin.

8. Sandstone

Sandstone is a composite filament that consists of PLA, infused with sand-sized chalk particles, to simulate the look of sandstone. Sandstone is ideal for figurines and multi-color prints, but ill-suited for handling due to its low strength and brittle nature.8

It was striking to observe that the majority of coatings reticulated on this material. All coatings showed paint lift of more than 50% and therefore had very poor adhesion. Spray filler might be the best option on this material.

Other 3D Printing Materials

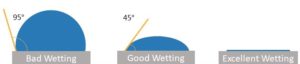

If you are using a material we did not include in our tests, or are not sure what filament was used for your print, there are two simple tests to determine adhesion with acrylics. One is the water drop test- an optical measurement of interfacial tension between a solid and a liquid. Simply place a drop or a small pool of water on your print and observe whether the water forms a bead or spreads out flat. In the latter case acrylics should ‘wet out’ the surface and adhere well. If the water drop beads up, so will the wet acrylic paint and an appropriate primer will be necessary for good adhesion. The second test would be the cross-adhesion, which was also used for these tests and described in Will It Stick? Simple Adhesion Testing In Your Studio.

Oil Paint on 3D Prints

3D printing filaments contain a number of additives such as flame retardants, UV-stabilizers and plasticizers. It was the UV-stabilizers, which prompted us to test, whether oil paint would dry normally on our test samples, since UV-inhibitors might hinder the oxidation process of drying oils.

Cobalt blue and French Light Sienna oil paint went on beautifully on all materials, including PLA, PETG, PA12, ABS, TPU and Sandstone. After 3-5 days (over the weekend) all paints were dry to the touch.

Varnishes

While 3D printing materials are constantly being improved upon, many, especially the more affordable ones, can be sensitive to UV-light, heat and moisture. Some printing materials can darken or change significantly in color.9 Covering prints with an opaque primer can hide these color changes. Varnishing or top-coating prints should further help to protect them, particularly if varnishes contain UV-light stabilizers.

We tested the Archival Varnish Gloss, MSA Varnish Gloss, and ColorMatic 2K Clear Coat directly on the 3D prints (PLA, PETG, PA12, ABS, TPU and SandstoneTM). The varnishes dried well on all prints, apart from the SandstoneTM. On SandstoneTM the MSA Varnish reticulated and remained wet and sticky for over a week, while the Archival Varnish dried normally. The ColorMatic 2K Clear Coat dried well on all printing materials, besides SandstoneTM on which it remained tacky for one day but then dried to an even and tack-free glossy finish.

Applications Where GOLDEN Acrylics Would Not Be Recommended

Anything can be 3D printed, but there are a number of application for which we would not recommend GOLDEN products.

- Objects intended for permanent skin contact, such as eye-wear or prosthetics. Our products are not intended for this kind of use and as our paints contain biocides, sensitive people could experience allergic reactions. For those kind of models paints should be used that are approved for skin contact. Acrylic paints are also thermoplastic, which means they can become soft and sticky when they warm up due to heat.

- Much handled objects, such as phone cases. Acrylic paints, while flexible and durable, are not meant to withstand the daily wear and tear of functional use. In those cases we would recommend a high quality top coat from good hardware store.

- Objects with food contact, such as bowls, cups, and mugs. Again, paints approved for food contact should be used. Our paints are also not dishwasher-proof, nor should they be submerged in water.

- Objects with permanent water contact, such as aquarium decorations. Acrylic films can take a few drops of water, but when immersed in water the paint swell, lift and peel off.

Bibliography

[1] “What Is PLA and What Is It Made Of?” <https://m.all3dp.com/2/is-pla-biodegradable-what-you-really-need-to-know/>, accessed 11/15/2019.

[2] Rohringer, Sean, “2019 3D Printer Filament Buyer’s Guide” <https://all3dp.com/1/3d-printer-filament-types-3d-printing-3d-filament/>, accessed 11/15/2019.

[3] Doepfer, Dorothée, “Material Science Part 5: Alumide – the ‘Hot Dog’ in the Polyamide Family”, <https://www.trinckle.com/blog/material-science-part-5-alumide/>, accessed 11/15/2019.

[4] Kivelä, Lamin, “Best Paint for Plastic (PLA, ABS, PETG, Nylon)”, <https://all3dp.com/2/best-paint-for-plastic-pla-abs-petg-nylon/>, accessed 11/15/2019.

[5] Johannes, “FDM-3D-Druck: ABS oder PLA? Was sind die Unterschiede?”, <https://3druck.com/lieferanten-haendler/fdm-3d-druck-abs-oder-pla-sind-die-unterschiede-2020380/>, accessed 11/15/2019.

[6] Stratasys, “PC-ABS”, <https://www.stratasys.com/materials/search/pc-abs>, accessed 11/15/2019.

[7] Molitch-Hou, Michael, “The Best and Most Unique 3D Printer Materials: Photopolymer Edition”, <https://new.engineering.com/story/the-best-and-most-unique-3d-printer-materials-photopolymer-edition>, accessed 11/15/2019.

[8] Flynth, Joseph, “Sandstone Filament: Properties, How to Use Them, and Best Brands”, <https://3dinsider.com/sandstone-filament/>, accessed 11/15/2019.

[9] Although ABS is one of the more stable filaments, ABS was shown to go from off-white to a deep orange-brown when exposed to 24 hours at 160°C/320 F as a means of accelerated aging, while PLA only went from white to a dark ivory color in the same test. Source: Zhang, Sung-Uk, “Degradation Classification of 3D Printing Thermoplastics Using Fourier Transform Infrared Spectroscopy and Artificial Neural Networks”, in Applied Sciences (available online).