©2007 Rich Niewiroski Jr.

Question: How often do they repaint the steel on the iconic Golden Gate Bridge? Answer: Every day, non-stop, repainting areas of corrosion (28 painters). Painting metal, especially metals exposed to variable environmental conditions is not something even our most advanced coating systems can stand up to over time, measured not in decades but in just years.

Metals include any elements which have metallic properties, including the ability to conduct electricity, being able to create permanent shape and form as well as deformed at average temperatures and typically have a luster. There are also a few elements defined as ‘metalloids’ that in some conditions behave like metals, such as boron, carbon, germanium, silicon and antimony.

Metals are typically grouped into two categories: those containing iron (ferrous metals) and those not containing iron (non-ferrous metals). The ferrous metals range from wrought iron, cast iron and many iron compounded materials containing carbon (carbon steel) as well as alloys of various other metals such as nickel steel, tungsten steel, chrome vanadium steel, etc.

The non-ferrous group contains all the other metals including copper, magnesium, lead, nickel, molybdenum, zinc, tin, brass and most importantly, aluminum. With this enormous array of possible choices for artists, the opportunity to shed light on using metals as a support cannot be covered in one simple article. Over the next several issues we will cover best practices for painting on metal supports. Each piece will detail their particular idiosyncrasies and some simply less suitable or appropriate for use as a surface to support the application of a painting.

Although many metals have found their way into beautiful and important painting supports for artists, aluminum is by far the most consistently used support material of all the metals for paintings. For this reason it is important to start our evaluation of using metals as a support with painting on aluminum.

Part 1: Aluminum

The element Aluminum is the most prevalent metal in our earth’s crust, but only within the last 125 years was it even feasible to work efficiently with this metal. Aluminum has become so ubiquitous in our world that it seems almost impossible to believe that previous to the mid 1800s, the pure metal was considered more precious than silver or gold.

Aluminum is now available in over 1,700 grades and finishing processes with tens of thousands of applications. While combing through much of the research in the field of coatings for aluminum and reviewing the many online ‘how-to’ guides it is quite a daunting task for any artist to feel confident in working with this material. Is it possible to reduce the clutter, refine our choices and define best practices when working with this material? Probably more realistic is to share good and better practices, as well as a nod for best practices for those wishing to go the extra mile in prep and / or cost.

We will first investigate choosing the most appropriate aluminum for a painting support. Next, the recommended preparation and priming of the aluminum support for subsequent painting.

Which Aluminum to Use

There are essentially 8 different grades of aluminum with a wide range of properties for working, welding, machining and corrosion resistance. The more important grades of aluminum for artists include those that have excellent corrosion resistance. These include the 1000, 5000 and 6000 series. Other grades of aluminum are used by artists, but are typically optimized for other valuable uses. Both 5000 and 6000 series are typically used for outdoor and harsh marine environments. The first number in the grading system is indicative of the primary alloy used with the aluminum to create its specific properties. In the 5000 series it is Magnesium. In the 6000 series it is Magnesium and Silicon. Commonly used grade series include 5005, 5052, 5083, 5456, 6005, 6061 and 6082. Each specific number denotes the particular levels of other alloys incorporated into the aluminum to provide specific properties of hardness, strength, workability, tensile strength, elongation, etc. For example, Aluminum 5052 contains minor quantities as well of Copper, Silicon, Iron, Magnesium, Manganese, Zinc and Chromium.

When purchasing aluminum sheets there is also typically another designation referring to its degree of tempering (most commonly an H or T followed by a number). This simply refers to the degree of processing the aluminum has undergone, whether from additional heat, strain or work hardening. For example, an aluminum sheet that has been coated with a heat treated paint system might have the designation H4 suggesting that the heat from the application of the coating has affected the properties of the metal. These designations are less critical for artists working with the substrate and much more important for fabricators working and machining the aluminum.

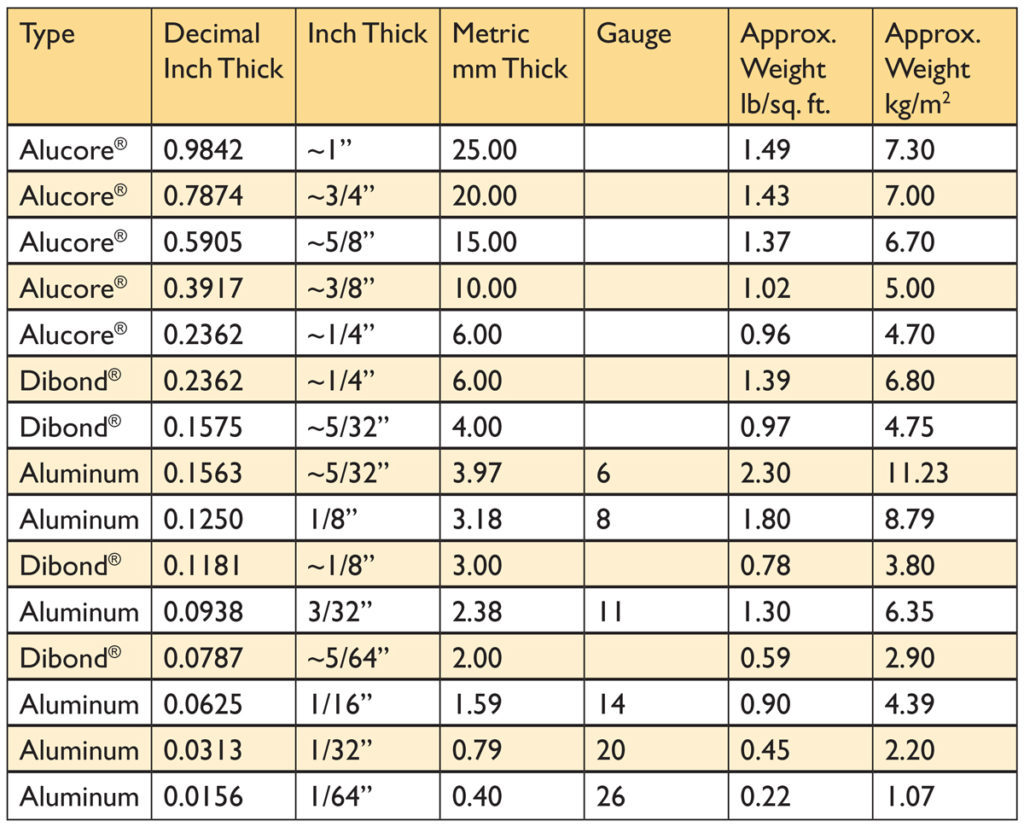

Aluminum sheets can be purchased in solid sheet form or laminated with inner cores of wood, solid plastic or honeycomb polyethylene plastic or aluminum thereby reducing its total weight. Many of these laminated forms can be shaped by manufacturers to conform to artist’s needs. From oval to multi sided, and in a range of cut-outs as well. These panels also typically have a limited range of expansion and contraction making them quite suitable for many coatings both flexible and rigid. Depending upon the overall dimensions required, solid sheets come in various thicknesses as does the solid core or honeycomb support, with larger works best supported by increasing the thickness of the aluminum sheet or core material. A rule of thumb for composite panels for the same level of rigidity or bending stiffness as sheet aluminum is to increase the overall thickness of the composite by 30-40%. This will still provide a reduction in the overall weight of the support. For honeycomb panels, the typical thickness is ½”. For larger pieces beyond 4 feet, a thicker panel may be appropriate. For solid core panels the most common thickness for smaller works (2 feet and smaller) would be 1/8” thickness. For works much larger, it would be common to use the ¼” solid core panel. Much of this depends upon the level of support provided by the framing, bracing or cradling of the work.

Aluminum supports come with a wide range of finishes, including non-treated, anodized, conversion coatings, coil coating, and painted with various systems including polyester paints, fluoropolymer resins (FEVE), polyvinylidene fluoride (PVDF) and other painted systems.

It is important that the artist is aware of how the aluminum support has been treated before preparing the aluminum or painting on the surface. The internet is full of examples of artists just going at it and painting on the raw aluminum, whatever the surface, and with great delight proclaiming, “It’s been hanging around for 7 years and the painting looks just fine”. This is always your prerogative as an artist but there are definitely better approaches that will be more likely to assure satisfactory results.

Uncoated aluminum is a very reactive metal that will quickly combine with oxygen in the atmosphere to begin creating an aluminum oxide layer. Eventually, as this process continues, especially in unprotected environments, it may lead to a more visible, white hydroxide layer on the surface. The aluminum oxide layer actually creates quite a corrosion resistant surface. Anodized aluminum is a process that takes advantage of the protective oxide layer and dramatically increases the thickness of this layer, making it the perfect choice for outdoor storage tanks and other structures that require greater corrosion resistance. Because it is a fairly porous layer it is also easy to chemically dye anodized aluminum. Unfortunately, an oxidized aluminum surface whether created naturally or through the anodizing process, is not the best surface for paint adhesion and will require additional measures to prepare them to successfully accept applied coatings.

The aluminum sign industry has created quite a few prepped and pre-coated aluminum surfaces, which with proper treatment, provide a very successful option for artists wanting to work on aluminum substrates. One of the most successful and most generally available of these aluminum laminates is Dibond®. This product is fabricated with two outer aluminum panels, .3mm thick, using a corrosion resistant, 5005 grade aluminum alloy. Its inner core is a solid polyethylene plastic which is available in different thicknesses, so the overall thickness ranges from 2mm (5/64”) to 6mm (1/4”). The aluminum surface is coil coated with a polyester lacquer system. Other aluminum panel systems are similarly prepped with various surface treatments and coating systems that dramatically reduce the steps required to prepare raw aluminum sheeting for painting. Although many artists simply begin painting directly on these prepared substrates, there are still several steps that most manufacturers have suggested to improve the performance of any applied paint or coating.

Preparing Aluminum Pre-primed Panel for Painting

Although some manufacturers suggest their panels don’t need any preparation before painting it is important to take at least a minimum level of precaution to clean your substrate. Brands such as AlumaCorr™, Signabond Lite® recommends at least wiping down the panel with a grease remover to remove any grease from previous processing or fingerprints. This could be as simple as using a lint free cloth with an appropriate grease remover (alcohol) that does not leave a residue (remember to keep your hands off the front of the panel).

Best practice is to also lightly abrade the surface after degreasing with wet/dry sandpaper. Make sure to avoid sanding through the applied coating. Then wipe off any dust from the grinding process with the alcohol wipe before painting. The supplier or manufacturer of your panel would be able to provide their best advice for their coating system. Dibond® and Alucore® recommend this process for subsequent applications of coatings:

1. Pre-clean with Ethyl- or Isopropyl alcohol (apply to a lint free cloth first and not directly on surface).

2. Follow with a light buff sanding using 360 Wet/Dry sandpaper.

3. Remove dust with cloth moistened with the alcohol.

4. Allow sufficient time to dry.

GOLDEN Materials and Application Specialist Scott Bennett, has written an article in JustPaint.org about best practices for painting on DiBond® (See https://justpaint.org/painting-on-dibond/)

Preparing Unprimed Aluminum Panels for Painting

With all of the choices of prepared aluminum composite panels, if you desire to work on a pure aluminum surface and want to maintain that aesthetic of a reflective metal, you may need to prepare your own panels. If you’ve chosen this route because you believe you can save money in the process, you may be surprised. To properly prepare a raw aluminum stock panel there is quite a bit of work that an artist must be willing to do to create a proper, most durable surface to paint on.

As described earlier, aluminum sheet metal of any grade will immediately start to oxidize upon contact with air. This aluminum oxide surface, although protective of the aluminum, is not a good adhesive surface for subsequent painting. Therefore, it is not best practice to paint directly on an untreated aluminum substrate.

For best practice to prepare an aluminum sheet for painting, three steps are required that will provide the most assurance that both the paint will remain attached and the metal will be less prone to continue to form disturbing oxidative products on the painting. These steps include degreasing (desmutting) the aluminum, then etching the surface by chemical or mechanical means to remove the oxide coating on the aluminum and then applying a conversion coating on the metal immediately to again reduce the level of the aluminum self-oxidizing. As much as it would be wonderful to share with artists that there are easily available commercial products that will make this work straightforward, I must share that the materials and techniques required are not typically within the reach of most artists, nor reflect how most typical studios are equipped.

Several years ago there were quite a few products in the marketplace, especially within the marine hardware universe that would both provide easy etching and coating solutions for the typical consumer. Almost all of these products are currently off the consumer market. The chemical etching solutions typically require a caustic soda or phosphoric or sulfuric acid to clean and etch the aluminum. The best coating systems required the use of the very toxic hexavalent chromium oxide (remember the film Erin Brockovich) system. Other safer systems using trivalent chromium or combinations of zirconium and titanium are not typically available within the normal consumer hardware stores. Some of these products can be found in automotive refinishing or commercial marine refinishing shops specifically for refinishing aluminum wheels and other automotive parts or aluminum hulls. Obviously these are not to be used unless one is willing to devote some time to learn how to deal with these chemicals as well as understand the appropriate disposal of these materials.

Essential First Step

If you aren’t interested in the full Monty, then it is critical to wash down the aluminum surface to remove any grease or oily deposits (especially from oily hands). While acetone can be used, more professional degreasers are available. For example, AWLGRIP® makes a product that one can find in marine hardware stores called Awlprep Wipe Down Solvent or POR Metal Cleaner Degreaser. A strong alkaline cleaner will also work to degrease the aluminum, yet many will also begin to pit the metal. It is important to use one that is safe on metals. Examples of consumer products include Simple Green® Extreme. Products like Ajax®, Borax® (20 Mule Team), and Mr Clean® will also remove the aluminum oxide coating and should be used in recommended dilution and in contact with the aluminum as briefly as possible. Do not allow these materials to dry on the surface and make sure to completely clean with sufficient water (deionized preferred) after use to avoid spotting. As always, use appropriate personal safety equipment to avoid dangerous exposure to these materials. The use of appropriate gloves is necessary to avoid re-contaminating the surfaces with skin oils. This process avoids paint delamination caused by grease, dirt or oils.

Taking it to the Next Level

The next step in best practice for preparing an untreated aluminum surface is to remove the oxidized layer. It is possible to remove the oxidized layers by mechanical methods, meaning sanding or grinding. Sanding the metal surface both removes the aluminum oxide coating as well as provides an etched profile of the surface that will aid in adhesion of subsequent coatings. If sanding, it is essential to avoid using other metal sanding materials such as steel wool which can imbed impurities into the aluminum and dramatically speed up the corrosion process. It is recommended to use a 3M Scotch-Brite™ Red Scuff pad. It is also best to avoid any sanding tools coarser than 80 grit. To remove marks created with these coarser papers, continue to sand using progressively finer and finer papers (200, 400, etc.). To remove sanding dusts it is best to use a tack cloth, blower or vacuum to pick up the particles.

Another route to etch an aluminum surface is to use a chemical etching system. There are resources, especially from marine hardware suppliers, that can provide several solutions. Alkaline etchants such as caustic soda will remove the oxidative layers. One product that will not only etch the aluminum surface but also prime the surface is AWLGRIP® Wash Primer CF Converter. It is a two component etching primer that can create an interlayer for subsequent paint applications. Other available etching primers typically have opaque finishes. POR® Metal Prep, TRANSTAR® 1K Self-Etching Primer, U-Pol® 1K Acid #8 Etch Primer or SEM® Self Etching Primers come in black, gray and green. Rust-Oleum® Self Etching Primer is a gray coat and is typically available at your local hardware paint supplier. All of these coatings require personal protective gear including gloves, eye protection, ventilation and manufacturer recommended respirators.

Clear Coatings

We recognize that many artists using the aluminum as a support are attracted to the reflective metal surface of bare aluminum. This is probably something you shouldn’t be preparing yourself. The most permanent surface for painting on aluminum that will leave a fairly bare aluminum look requires the application of a conversion coating. A conversion coating is a chemical finish that reacts with the surface of the aluminum to create a natural oxide coating that inhibits and slows further oxidation and when combined with the other processes, creates a better bonding surface for subsequent applications of paint. The most preferred material for this process is a chromic conversion coating. This is a process that requires both appropriate personal as well as environmental and industrial safe guards. It is a process that requires practice and timing to get this right and must proceed right after all the other processes are complete to assure that the surface of the aluminum has not begun to oxidize. There are several sites that will give advice as to how to complete this process. Although the information above provides a brief survey of products and a brief explanation of the process, I advise our customers wanting to work on aluminum, to have your materials surfaced by a professional aluminum converter or to use factory prepared aluminum panels.

Anodized Aluminum

Anodising is an electrolytic process that is used to increase the thickness of the surface oxide films on aluminium. The resultant films are hard, durable and inert and have better corrosion resistance and strength compared to finishes produced by chemical processes. The anodic films are normally between 5 and 25 microns thick depending on the end use, in particular, how aggressive the end-use environment is. Anodized aluminum can be a great surface for using dyes to color the aluminum. Unfortunately they are not the best surfaces for adhering a paint layer as the aluminum oxide creates a matrix that creates a fairly hard glassy surface. There is a variety of opinions, and artists have shared that they’ve been successful with painting on anodized aluminum. This is not our advice, as most professionals involved in preparing anodized aluminum recommend removing the oxide coating and starting the process as if it was bare metal.

Aluminum is a beautiful reflective and stable surface. Using the proper aluminum support will dramatically increase the lifespan of your artwork.

About Mark Golden

View all posts by Mark Golden -->Subscribe

Subscribe to the newsletter today!

No related Post

Thank you for the information on painting on aluminum. I am using a product not listed here. Alumacomp may have been introduced after this article. This product is supposed to be covered with a polyester coating I believe. Also, will Self Leveling Gel reduce brush stroke evidence when applied under varnish? Thank you for your help with this matter. Chris Bell

If your aluminum panel has a polyester coating, you could follow our recommendations for painting with acrylics on DiBond found here: https://justpaint.org/painting-on-dibond/

Self Leveling Clear Gel would likely not reduce brushstrokes under varnish. We recommend using our Isolation Coat product on an acrylic painting before applying varnish. Isolation Coat is much thinner and will shrink even further when drying to a very thin film. Clear Leveling Gel (formerly known as Self Leveling Clear Gel) is a thicker product that does not level completely. It will also craze if applied too thickly. We do not recommend mediums as topcoats. Acrylics will shrink around texture instead of filling the texture in, so brush stokes will telegraph through layers. The best bet is to apply thinly and evenly with a soft synthetic brush and do not overwork, meaning when it starts to dry, because this will leave more texture. More information about Isolation Coats and Varnishing can be found here: https://www.goldenpaints.com/technicalinfo/technicalinfo_varnishresources

If you have any further questions, feel free to contact us at [email protected]

Thanks Mark

This is incredibly useful.

I have been scouring the internet for weeks for this information – how to achieve an archival quality substrate in aluminium. Like anything in art definitive information is very hard to find, while there are plenty of opinions of various and often dubious quality.

I was surprised at the end of the article that it was written by the maker of my acrylics, which I had chosen for the same reason, serious archival quality (and great pigments).

Again very much appreciated, I have ordered my sheets and have a solid plan moving forward thanks to your efforts.

Keep up the great work

James

James, thanks. We typically pose ourselves the research based on the questions we get from artists. Eventually it becomes inevitable that we can’t find the information either, so we set about doing the first hand research to try to get at least the most accurate opinions of the day. Even then we find ourselves having to regularly update our findings as new research is available. We’re a bunch of material geeks, that are inspired by the artists that we work with. Thanks so much for your comments. Warmest regards, Mark

Hello, Joye.

Thank you for your question. You’ll likely need to apply a smooth primer onto the polyester-coated surface. Rustoleum makes a “Direct to Metal (DTM) Bonding Primer” product called XIM “UMA” (Urethane Modified Acrylic). On their website, they cite it can be used on coated aluminum siding. https://www.rustoleum.com/product-catalog/consumer-brands/xim/bonders/advanced-technology-uma-white I do not believe we have done any adhesion testing of oil paints on top of this primer, but having tested the UMA product before, We do know that this levels extremely well and results in a smooth surface. Being a primer product, it should provide adhesion to a range of paint types. Contact us at [email protected] if you would like to expand upon this discussion.

– Mike Townsend