Dirt damages the beautiful surface of watercolor on paper, and ultraviolet light fades delicate washes. Watercolor paintings need protection when on display. Acrylic sheeting and art conservation glazing options have widened the choices beyond traditional framing behind glass. However, museum-grade UV non-reflective glass and acrylic glazing can be expensive and add weight when shipping artwork. Are there alternatives that might offer equal protection against damaging UV light?

Varnishing offers one way to liberate watercolor painting from the cage of glass and frame. We have received numerous questions about varnishing watercolors, and even have an Application Information Sheet discussing the process.1 Since GOLDEN Varnishes shield paint from UV light, they should protect against light-related fading of watercolor paint. How does our Gloss Archival MSA Varnish with UVLS2 compare with other protection options when watercolor on paper is exposed to light? We conducted testing to find out.

Comparative Lightfastness Protection Testing

Protecting watercolor paintings from potential light-related fading can be an important display consideration. Watercolor paint has very little binder, which exposes the pigment particles more to light than if the same pigment were in acrylic or oil paint. The American Society for Testing and Materials (ASTM) provides separate lightfastness tables for pigments in each of these painting mediums, and a pigment often has less lightfastness in watercolor.

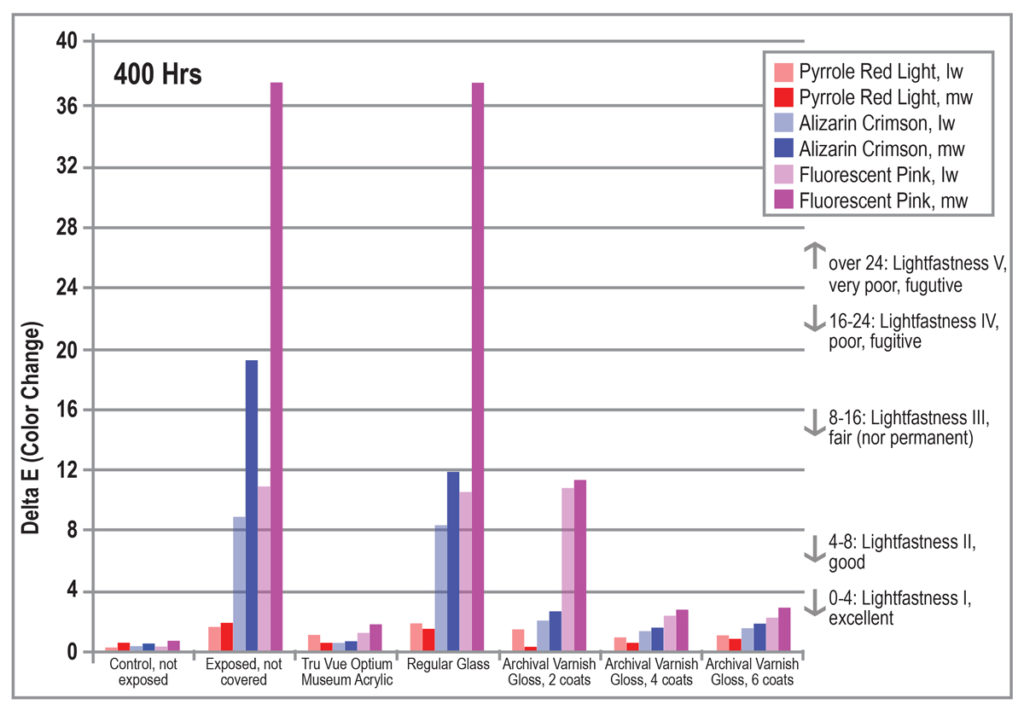

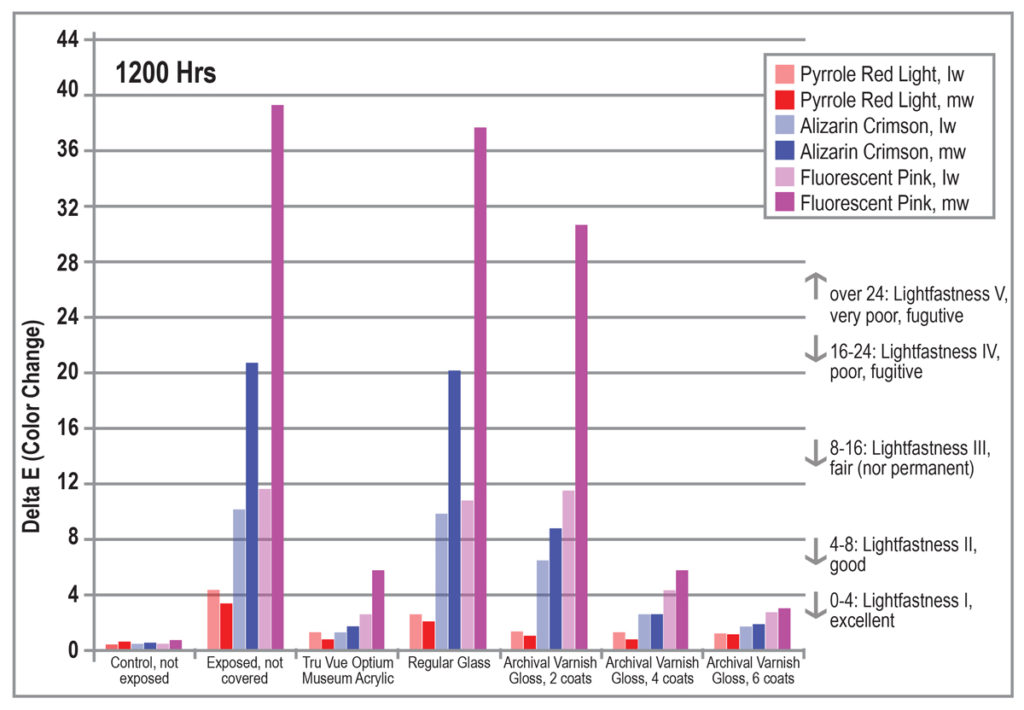

ASTM refers to a “Delta E” unit when determining how much change exposure to light creates in paint.3 A single unit of Delta E is the minimum amount of change noticeable to an average viewer. For lightfastness of artists’ paints, ASTM designates from 0 to 4 Delta E units of color change as Lightfastness I (Excellent), over 4 to 8 as II (Very Good), over 8 to 16 as III (Fair, Not Permanent), over 16 to 24 as IV (Poor, Fugitive), and a Delta E greater than 24 units as V (Very Poor, Fugitive). High quality artist-grade paints are Lightfastness I or II.

For comparative lightfast protection testing, we measured Delta E in light and medium watercolor washes from three different colorants: 1) PR255 or QoR Pyrrole Red Light, rated Excellent (Lightfastness I) in watercolor by ASTM; 2) a fugitive fluorescent pink dye; and 3) PR83 or true Alizarin Crimson. Alizarin Crimson was one of the pigments first tested when ASTM developed lightfastness testing procedures for artists’ paints, and ASTM rates paints made with this pigment as having Poor (IV) lightfastness in watercolor.4 Since QoR® Modern Watercolor does not contain paint with PR83 or fluorescent dye, our formulators created these two watercolors for our test. The dominance of fugitive paints in our investigation created a ‘worst case scenario’ to push the limits of the coating’s ability to provide protection against light exposure.

Diluting each of the paints with distilled water, we painted multiple medium and light intensity washes (mw, lw) on Arches® Natural White 140 lb. (300 gsm) Cold Press Watercolor Paper. The dilution ratio and wash intensity were judged by eye. We evaluated dry washes for evenness and similarity in value, and then flattened those selected. Squares of each wash would be kept as unexposed controls or protected by the coatings to be tested for lightfast protection.

Before exposing the swatches to light, we needed a starting point reading against which to compare potential changes to color. We used an X-Rite VS450 spectrophotometer with CIE L*a*b* color space (CIE 1976) to read and record color in five spots on each watercolor wash square. Averaging these readings provided a pre-exposure control analysis of the color on that particular square.

We employed a QUV booth to subject the swatches and their protective coatings to light using accelerated UV exposure testing. The QUV’s UVA fluorescent ultraviolet bulbs provided a UV spectrum similar to sunlight through window glass.5 Each 400-hour cycle of accelerated exposure provided the rough equivalent of about 33 years of museum lighting. Three separate sets of swatches were exposed for 400, 800, and 1200 hours in the QUV, which created comparative readings for approximately 33 years, 66 years, and 99 years of illumination. Moisture levels in the chamber fluctuated with the ambient low humidity of a New York winter, and testing temperature was set to 60° C.

Painted swatches in the QUV were either bare or covered with a potential protectant, as our test targeted the following coating options:

- No Coating: Not covering the watercolor on paper at all would be a worst-case scenario.

- Regular Glass: This was the original option when framing a watercolor, and many artists continue to use it.

- Tru Vue® Optium Museum Acrylic®:6 Described as an Art Conservation option, this blocks up to 99% of UV, providing a gold standard of lightfast protection when framing a watercolor. It also resists abrasion, will not shatter, is anti-static, and non-reflective.7

- GOLDEN Gloss Archival Varnish with UVLS in two, four, and six sprayed layers: This is the aerosol version of our MSA Varnish. What protection does Archival Varnish offer, and how do the results compare to the other options being tested?

This range of coatings allowed us to test possibilities in use by artists today. The potential differences between Delta E readings of swatches exposed through regular window glass, Tru Vue Optium Museum Acrylic, and GOLDEN Archival Varnish with UVLS were especially important.

After exposure, we read each square again in five spots and averaged the readings into a post-exposure analysis of the color on that square. Again using the spectrophotometer, we compared the pre- and post-exposure readings to determine the amount of change for that particular square. This change is its Delta E number. Each square represents a specific combination of watercolor paper and watercolor paint used, wash applied, protective coating (if any), and exposure hours. In all, each of the 342 squares was read 10 times for a total of 3,420 spectral readings. We averaged the three swatches for each test option into a single Delta E representing that test combination.

Lightfast Testing Results

Tables 1 and 3 present the averaged results of 400 and 1200 hour exposures. As can be seen in these tables, even the non-exposed control swatches show a small variance between their comparative averages. This may be attributed to inconsistencies in hand-painted washes and slight differences in placement when being measured. Although the chart is not included here due to space limitations, the 800 hour Delta E readings (Table 2) can be found in the JustPaint.org version of this article. It should be noted that while our results provide information on behaviors within the strict parameters of this test, watercolor and UV protectants might interact differently in other applications or over time in real-world lighting situations.

At 400 hours, protection provided by Tru Vue, four coats, or six coats of Gloss Archival Varnish provided excellent protection for the watercolor test swatches. All of their painted samples remained under Delta E 4 and within the ASTM Lightfast I (LF I) range, with Tru Vue providing slightly better protection. All Pyrrole Red Light washes in the 400 hour exposure stayed LF I. In comparison, while two coats of Gloss Archival Varnish protected the other washes, Fluorescent Pink earned LF III ratings for both washes. With glass, both of the Alizarin Crimson washes and the light Fluorescent Pink wash earned LF III, and the medium Fluorescent Pink fell to LF V. After 400 hours of exposure, the unprotected Alizarin Crimson and Fluorescent Pink light washes both earned a LF IV. Unprotected medium washes fell to LF IV for Alizarin Crimson and LF V for Fluorescent Pink.

At 1200 hours, all of the washes remained in LF I when protected by six coats of Gloss Archival Varnish. Tru Vue kept all but the Fluorescent Pink (FP) medium wash in LF I, with this wash falling to LF II. With four coats of Gloss Archival Varnish, both Fluorescent Pink washes were in LF II and the other washes remained in LF I. Under two coats of Archival Varnish, a light wash of Alizarin Crimson (AC) rated LF II and a medium wash LF III; a light wash of Fluorescent Pink fell to LF III and a medium wash to LF V. Regular Glass and ‘exposed not covered’ readings for light washes of Fluorescent Pink and Alizarin Crimson were LF III. Both of their medium Alizarin Crimson washes came in at LF IV, and the medium Fluorescent Pink earned LF V.

In keeping with its ASTM rating, Pyrrole Red Light remained in the LF I category for all but the ‘exposed not covered’ light wash at 1200 hours, which earned Delta E 4.23. This is slightly over the border into LF II. Since this pale wash had less pigment than the 40% reflectance wash used for ASTM lightfast testing, this rating is not surprising.

Varnishing changes the aesthetics and nature of watercolor on paper (Figure 1). However, because the current testing only focused on lightfastness vs aesthetics, this issue was compounded by our choice to only apply Gloss varnish since it allowed for the best color measurements. The downside is the fact that multiple layers of Gloss varnish in particular can create an almost laminated look. Because of that, we hope to show in a future article some of the ways to minimize this by using a combination of Gloss and Matte varnishes. Looking at current results, six coats of Gloss Archival Varnish did an excellent job with lightfast protection. However, six coats also filled in the paper texture and created an extremely glossy acrylic surface. From certain viewing angles, light reflecting off this coating obscures the painting. With four sprayed varnish coats, the surface is less glossy, the paper texture still has a presence, and reflective light is broken rather than continual. With two coats, there is more texture and less varnish, which results in a very slight glistening quality with reflected light. Varnishing also can create permanent changes to color and light-dark values within the work. It is always good to test to be sure the changes are acceptable.

In contrast, the almost invisible and removable protection offered by Tru Vue® offers very little change to the aesthetics of the watercolor, and allows the surface of the paper to maintain its unique and subtle interplay with light. When taking into account lightfastness protection, preservation of a watercolor on paper’s unique surface, and the traditional aesthetics of a watercolor painting, Tru Vue® provides an excellent option.

Conclusions

Our investigation used a majority of paints with poor lightfastness, which provided a harsh test of protection against the damage created by ultraviolet light. Regular glass and two coats of Archival Varnish (Gloss) did not prove effective against fading of fugitive paints due to UV light. Protection increased with more layers of varnish. Although four coats of Varnish provided some protection, six layers of Archival Varnish (Gloss) kept all of the test squares within a Lightfast I category when exposed to the equivalent of about 99 years of museum lighting. Except for the Fluorescent Pink medium wash, Tru Vue® Optium Museum Acrylic® also kept all colors to Lightfastness I with 1200 hours of exposure. Regular glass did not provide this protection. Pale washes of even LF I paints may fade with a century of exposure to ultraviolet light, and our testing suggests that the protection of as few as two layers of varnish can help prevent those color changes. For artists who embrace the aesthetic changes created by varnishing and are interested in pushing the boundaries of traditional watercolor, GOLDEN Archival MSA Varnish offers a valuable option for lightfastness protection of transparent watercolor on paper.

1Golden Artist Colors, “Application Information Sheet: Varnishing Watercolors with GOLDEN Products,” http://www.goldenpaints.com/technicalinfo/technicalinfo_varnwatercolor (accessed 4/4/2016).

2UVLS stands for Ultraviolet Light Stabilizers and is the component in the varnish that provides lightfastness protection to the artworks over which they are applied.

3For more information, see Sarah Sands, “Delta E: A Key to Understanding Lightfastness Readings,” Just Paint, https://justpaint.org/delta-e/ (accessed 3/30/2016). According to ASTM D4303-03 “Standard Test Methods for Lightfastness of Colorants Used in Artists’ Materials,” a spectrophotometer and the CIE L*a*b* color space (CIE 1976) are to be used to determine Delta E. This analysis of color change is based upon comparing pre-exposure spectrophotometer readings and post-exposure readings of a paint’s color. Larger numbers represent more damage from light and greater change to the color.

4ASTM D5067 “Standard Specification for Artists’ Watercolor Paints,” p. 2, 6.

5“Sunlight, Weathering & Light Stability Testing,” Q-Lab Technical Bulletin

LU-0822, rev. 2007, p. 6, Q-Lab.com. http://www.q-lab.com/, http://www.q-lab.com/documents/public/cd131122-c252-4142-86ce-5ba366a12759.pdf (accessed 4/12/2016).

6“Tru Vue® Optium Museum Acrylic®,” Tru-Vue.com, http://Tru-Vue.com/solution/optium-museum-acrylic/ (accessed 3/30/2016).

7“Product Comparison for High Performance Acrylic and Glass Solutions,” Tru-Vue.com, http://Tru-Vue.com/wp-content/uploads/2015/12/TRU_5954_AcrylicSellSheet_V2.pdf and

“Acrylic Collection Fact Sheet (English),” http://tru-vue.com/museums-collections/samples-literature/ accessible via “Technical Info and Resources,” “Tru Vue® Optium Museum Acrylic®,” Tru-Vue.com, http://Tru-Vue.com/solution/optium-museum-acrylic/ (accessed 4/11/2016).

About Cathy Jennings

View all posts by Cathy Jennings -->Subscribe

Subscribe to the newsletter today!

No related Post

Do the tables show that the medium wash samples of fluorescent pink and alizarin crimson faded more than the light wash samples of these two colors? If so, I would have guessed the opposite result — that a more diluted wash would fade more than a less diluted (more concentrated) wash.

Hello Cynthia,

Thank you for your question. Yes, that is what the tables show, and at first glance it does seem like the medium wash would fade less since that is what should happen with lightfast pigments. However, in this case there are two things to keep in mind. First, think about the contrast between the paper and a light wash, and the paper and a medium wash. When it is first applied, a medium wash covers the surface with more pigment and more intense color than a light wash does, and so differs more from the paper. Then remember that Fluorescent Pink and Alizarin Crimson are both fugitive colors that fade away with exposure. A more intense wash provides more pigment to fade. This fading exposes more paper and creates a bigger difference between the pre-exposure and post-exposure readings, which creates a higher Delta E for the medium wash.

Thanks — the explanation is much appreciated!

Thank you for such an informative article. I’m wondering if it’s acceptable to use this varnish over QoR watercolors on Yupo. Thanks for your help.

Hello Sandy,

What a great question! We know Yupo is popular with painters using acrylics and watercolors. Acrylics do not adhere permanently to polypropylene plastics, and Yupo is made from polypropylene pellets. While our testing is limited, we were able to pull dry acrylic paint off of Yupo and this causes us concern about adhesion. We have not tested adhesion on all Yupo varieties, and we have not tested the adhesion of Archival Varnish on Yupo. It might work beautifully, however we would be cautious since Archival Varnish is an acrylic.

Should you wish to do adhesion testing, you might paint half of a sheet of Yupo with watercolors using the techniques and paints employed in your artwork. Then coat both the bare surface and the painted surface of the Yupo with multiple Archival Varnish layers to seal the surface. Let this dry at least three days, and then do adhesion tests on the Archival Varnish directly on the Yupo, and on the Archival Varnish over watercolor on the Yupo. Since adhesion can improve with time, it would be good to repeat the tape test after a week or so if the varnish is coming up. We use crosshatch adhesion tests like that described in the Just Paint article “Test for your Application“.

Finally, Legion Paper is a paper merchant that represents Yupo, and they have resources for artists. You might find their forum of interest, as there are discussions of adhesives and topcoats in relation to Yupo:

Legion Paper, site search for “Yupo”

Legion Paper, Forum

We hope this is helpful, and look forward to your next questions.

Best Regards,

Cathy

Would you still mat and frame with glass a watercolor coated with GOLDEN Gloss Archival Varnish with UVLS ? Would the painting then stick to the glass?

Hello Karen,

A well varnished watercolor that has been adhered to a rigid support, or a varnished watercolor on canvas, could be exhibited without the protection of glass. Varnishing will create permanent changes to the watercolor, though, so practice and testing should be done first. We hope this is helpful, and if you have more questions don’t hesitate to give us a call!

Best Regards,

Cathy

Might this also work well with pastels? Putting too much gloss varnish would give them a laminated look as you describe for the watercolors, but matte medium could possibly work, I think. Has any testing been done with other mediums? Thanks.

Hello Ray,

Thank you for your question. We have not done a lot of varnish testing over pastels. What we have done indicates that there may be dramatic aesthetic changes to the pastels once enough varnish is applied to actually protect the surface. Spraying can be a better application method, as the physical act of brushing moves the pastel on the surface. We would advise testing if you wish to see what occurs, perhaps starting with gloss varnish (over dark saturated colors) and ending with matte if the shiny surface is not desired. We suggest starting with gloss since applying a matte product directly to a highly absorbent surface sometimes causes the matting solids to be more visible.

We hope this is helpful. Please fell free to call us in the Materials Specialist Department if you have more questions (800-959-6543, 607-847-6154).

Cathy

My concern would be about the watercolour paper and the effect of moisture. Even if you coat the painting with varnish and frame without glass, the paper is still vulnerable. I’m always looking for a way around glazing, but that WC paper has to be protected.

Hello Rebecca,

We agree with you, even heavy weight watercolor paper should be protected. One option might be using a museum-quality backing board behind the paper before the varnished work is framed. This would not halt infiltration from moisture, but it will provide support. Artists sometimes adhere the paper to a permanent rigid backing, such as coated aluminum panels. We also have spoken with artists who paint on watercolor grounds applied to supports other than paper, and then varnish the finished work once all is dry.

We thank you for your input, and wish you happy painting.

Cathy

Why was Museum Acrylic chosen as opposed to Museum Glass?

Hello Rebecca,

It was to some extent a subjective choice, as museum glass of the same high quality should provide the same long-term uv protection as the museum acrylic we tested. There might be greater diversity in use, as paintings protected with acrylic glazing might be lighter in weight and easier to ship than paintings glazed with glass.

Warm Regards,

Cathy

Is there a similar Matt product that would not leave a shiny surface? I want to coat large paper doors made from washi. I am looking to spray a liquid product through a large airbrush. Thanks for any tips. You are obviously ver knowledgeable.

Hello Sarah, The Archival MSA Varnish does come in both Satin and Matte. There are two other Just Paint articles which you might find of interest, both related to varnishing watercolor on paper. They may be found here and here.

For best results, we recommend starting with gloss varnish layers until the surface is no longer absorbent before switching to the varnish needed for the final sheen. Please keep in mind that our varnishes are intended for fine art applications, and do not hold up well on functional surfaces which might be touched or need to be cleaned. For larger areas, it is also possible to use spray equipment to apply diluted MSA Varnish. We hope this is helpful!