Artists like to paint on many kinds of surfaces and objects and with many types of media, but the surface or the paint may not be compatible. We understand that most people would not have standard cross hatch adhesion testers at home, so we would like to provide a way for artists to do a simple test to determine if the paint will adhere to the surface or to other layers of paint.

Testing before applying on your final artwork would be crucial. It’s no fun when you spend hours toiling over a painting only to find it has issues later, so doing a test beforehand with the exact materials you plan on using could be a real time saver and save you from heartbreak!

Allowing the proper dry time before doing the adhesion test is also essential, as some surfaces may need more time than others to fully cure, resulting in what might look like adhesion failure at first, but can significantly improve by simply waiting longer. A thin film of most Heavy Body or Fluid Acrylics takes around 3 days to initially cure at room temperature, while a thick film could take weeks or even months to cure depending upon the thickness, the environment and the substrate. A slower drying paint like High Flow and the even slower drying and slower curing paint like OPEN, could take a significantly longer time to see good adhesion. It may also take some more time to see good adhesion on a non-porous surface like Plexiglas® for example. Acrylics dry through evaporation; first the water evaporates, followed by other volatiles, and on a non-porous surface, the only direction for these to evaporate is up. On canvas, however, they could also evaporate through the back. In a very humid environment, it could also take longer for the paint film to dry and cure.

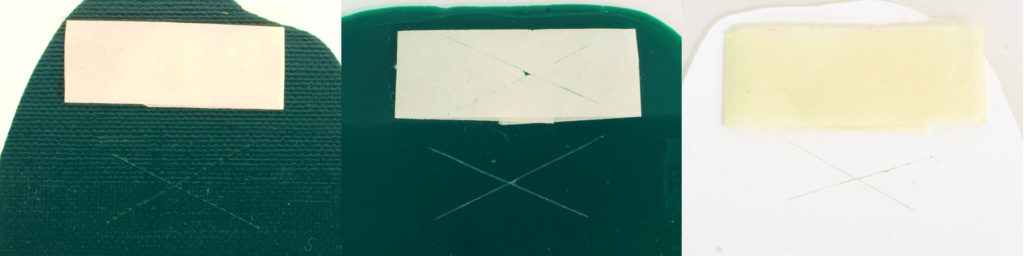

The process is as follows and uses common tools you likely already have in your studio. Make sure the surface being tested is clean and dry. Apply the paints or mediums in the same layers you plan to use on a sample of the surface you plan to use. Allow to fully cure for best results. For a thin film of Heavy Body or Fluid Acrylics, this usually takes about 3 days. You can start the test after 24 hours, then test again at 48 and 72 hours to look for improvement. If you still have failure, then try testing again on a weekly basis if needed, especially on a non-porous surface. Using an X-ACTO® or utility knife, make two cuts in the film, 1.5 inches (4 cm) each that intersect in the middle, in an “X” formation. ASTM (American Society for Testing Materials) recommends that two of the angles be between 30° and 45° as shown in Image 1. Make sure the cuts penetrate all the films being tested and down to the substrate if adhesion to the substrate is what is being tested. Brush away any material removed from the cuts. Use 3 inches (7.5 cm) of masking tape, the off-white kind and not low tack painter’s tape, and apply the tape with the center over the intersection of the cuts and running in the same direction of the smaller angles. Rub the tape firmly with a pencil eraser or the back of your fingernail, but leave one end free. Grasp the free end of the tape and, in one swift motion, pull off the tape rapidly back upon itself, like pulling off a BAND-AID®. It can be helpful to do more than one of these tests on your piece. Determine the level of adhesion by observing the area after tape removal and observing the tape. The best result would be no peeling or removal of the paint. If there is a trace left on the tape in the form of a faint “X”, this would still qualify as good adhesion. Jagged removal along the incisions on either side, would show adequate adhesion. Removal from most of the area of the “X” on to the tape or removal beyond the area of the “X”, is evidence of poor adhesion. If you are testing multiple layers and only one layer is removed, then that would show failure of that layer to the one underneath. Where the failure occurs is very telling.

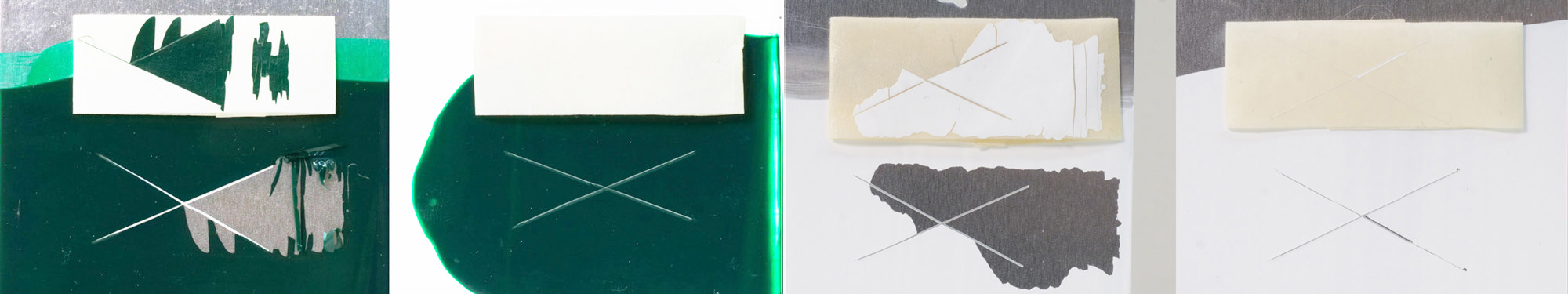

If you experience adhesion failure, an appropriate primer may be needed as a “bridge coat”, as seen in image 2 where the paint failed on bare aluminum, but adhered well on top of a Direct To Metal primer.

For more information about testing for your application and details about cross hatch adhesion testing, follow this link: https://justpaint.org/testing-for-your-application/

As always if you have any questions, feel free to contact our Material Specialists at 800-959-6543 or [email protected].

About Stacy Brock

View all posts by Stacy Brock -->Subscribe

Subscribe to the newsletter today!

No related Post

Very useful, thank you for this!

You are quite welcome! It is our pleasure!

I’ve been intrigued by the idea of using a aluminum support, but put off by the uncertain contents, longevity and chemical effects of metal primers. They seem to function well in the short term, but the first two goals of industrial metal primers seems to be to protect the metal, and not delaminate. Not undesirable ends, but one often gains an inference that the coating is like galvanizing, ultimately sacrificial, and not intended to last the centuries. Indeed when some of the contents are declared, zinc is often a component. Not something I trust to have in contact with oil paint.

Hi Marc,

Aluminum is gaining in popularity due to the dimensional stability and lightweight nature. The most popular aluminum composite panels used for signage and artwork are made by Dibond, which tend to have either a clear coating or polyester coated surface. These products have performed rather well in our testing when prepared properly and if using raw aluminum, we always recommend an appropriate Direct To Metal primer, which as you say are designed to block oxidation to deter delamination. We do not make these primers, so cannot speak to the longevity of these products, but again they have performed well in our testing thus far aside from some yellowing. The issue is that are are thousands of types of aluminum, so we would be hard pressed to give advice about how to treat all of these or make blanket statements about aluminum in general. We have not tested aluminum panels in conjunction with oil paints. The environmental conditions in which a painting is stored also greatly contributes to the longevity of the artwork as well.

You may find our article written by Mark Golden for our Just Paint newsletter about aluminum as a painting substrate interesting and there is a section which discusses options of primers that contain no zinc chromate:

“One product that will not only etch the aluminum surface but also prime the surface is AWLGRIP® Wash Primer CF Converter. It is a two component etching primer that can create an interlayer for subsequent paint applications. Other available etching primers typically have opaque finishes. POR® Metal Prep, TRANSTAR® 1K Self-Etching Primer, U-Pol® 1K Acid #8 Etch Primer or SEM® Self Etching Primers come in black, gray and green. Rust-Oleum® Self Etching Primer is a gray coat and is typically available at your local hardware paint supplier. All of these coatings require personal protective gear including gloves, eye protection, ventilation and manufacturer recommended respirators.”

Here is a link to the entire article: https://justpaint.org/painting-on-metal-an-introduction/

If painting indoors, our Acrylic Gesso also contains no zinc and could be used on the coated panels, or if uncoated on top of the commercial primers. Here is a link to our article about painting on Dibond: https://justpaint.org/painting-on-dibond/

We hope this is helpful and if you have any other questions., please feel free to email us at [email protected].

Best,

Stacy

Thanks for your reply, it’s given me much to think about.

In the meantime I’ve been using a polyester canvas glued to MDO plywood panel.

Kind Regards,

Marc.