People often ask us what we would recommend as a wood panel option for use as a painting substrate and one that often comes up is MDO (Medium Density Overlay) plywood. While used by many muralists, as well as some panel painters, it is probably the least known of the various types of plywood you might hear about. Because of that, we thought it would be good to discuss what MDO plywood is, why and when one might use it, how it is prepared, and a summary of some of its attributes and potential drawbacks.

Medium Density Overlay

MDO plywood is an exterior plywood produced with a resin-impregnated Kraft paper overlay. An overlay being a thin sheet of paper, plastic or metal that is bonded to one or both sides of a substrate in order to enhance a working face for special-use applications. Plywood that is enhanced with a MDO will combine the structural attributes of plywood with an upgraded facing that masks wood grain, increases durability and provides a smooth texture for easy painting. The MDO overlay is typically opaque and wood-toned, but can vary depending upon the manufacturer.

There are two forms of MDO plywood, a concrete form designed for industrial applications and a general form designed to be a paintable surface. The concrete form of MDO has a higher percentage of resin present in the overlay for increased durability, but it also contains a chemically reactive release agent to allow for easier separation from concrete molds. Of the two, the general MDO plywood would be best suited for painting. (APA, 2011)

MDO may not be a readily available product in most hardware stores, but it can usually be ordered in and picked up. It is important to make note of how different manufacturers prepare an MDO panel by either pre-priming or specifying the need for appropriate priming before use.

When and Why to use MDO

MDO plywood would be a suitable option for exterior muralists and panel painters working in either acrylics or oils. Understanding a little bit about how a MDO panel is constructed, the type of resin used and how the plywood is classified can provide some insight into why it might be an appropriate wood panel option.

The Resin

Most wood panel products are manufactured using either a urea formaldehyde or a phenol formaldehyde adhesive. The difference between the two and why one would be used over another has a lot to do with urea formaldehyde being a water resistant adhesive and phenol formaldehyde being waterproof. Manufacturing cost and emissions are also factors. (APA, 2015) MDO plywood uses a phenol formaldehyde resin, also known as a phenolic resin, to adhere and saturate the overlay as well as bond the plywood veneer together. Phenolic resin is highly compatible with wood based products and will quickly penetrate into and wet-out cellulose fibers in its liquid state, then cross-link and harden when thermoset under heat and pressure. The immediate benefits being high mechanical strength, chemical, moisture and heat resistant properties. (Plenco, 2018) For a painter or muralist looking for a stable wood panel option, this increased resistance to moisture absorption correlates with a decrease in swelling when the panel is in conditions of high relative humidity. This results in an overall increase in dimensional stability. (Ebuka, Ezeh, Gimba, Mamza, 2014) The overlay itself will have a higher percentage of phenolic resin than the panel and will often be oriented with its strongest dimension perpendicular to the wood grain. This is designed to impart these structural benefits as well as improve resistance to surface checking or cracking.

Exposure Classification

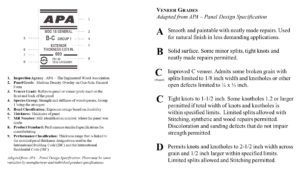

There are various exposure classifications of plywood, each related to the quality of the veneer and the performance of the bonding adhesive. MDO is classified as an exterior plywood as specified by the APA voluntary PS 1-09 Structural Plywood Standard. (APA, 2010) This states that D-grade veneer is not permitted in exterior plywood and that an MDO panel should be composed of C-grade or higher veneer throughout with B-grade facings. This standard also requires that an exterior plywood be bonded using a waterproof adhesive such as a phenolic resin. An overabundance of voids in the wood or a water resistant, not waterproof adhesive, could create opportunities for water to migrate through the panel, so these specifications are designed to provide improved structural resistance to moisture. An exterior plywood is expected to be suitable for permanent exposure to weather and changing environmental conditions. (APA, 2012) This classification does not relate to physical wear and tear or biological resistance to mold and mildew. The bond between the plywood and the overlay is also treated to the same standard as the bond strength between the layers of veneer. (APA, 2010)

Preparation for Use as a Substrate

Before preparing a MDO panel for painting, if possible, it can be helpful to read the manufacturers specifications to see if the panel has been specially treated or pre-primed. Typically, if pre-primed, manufacturers will apply a thermo-set acrylic to both the sides and working faces of a MDO panel, which will appear opaque and white. Make note of whether it is compatible with oil paints or latex (waterborne) paints when working in acrylics. If ever unsure, it is possible to do an adhesion test, which can be helpful if this information is not available or further assurances are required. Always test if you are unsure.

When using a MDO plywood outdoors that is unprimed, it should be appropriately edge sealed and primed on both sides with a high quality wood primer that is compatible with latex (waterborne) paints. A light sanding is recommended prior to priming, to promote adhesion and reduce any potential evidence of wood grain. It is still possible for the grain of the wood to raise or the surface to become uneven and transfer through the overlay. This can also be a factor when displaying works or working in an environment with conditions of moisture or high humidity. (APA, 2018) Once the painting or mural is complete, we recommend applying an isolation coat and 2 or more coats of our MSA Varnish. Here is are two Just Paint Article that goes in to more detail on preparing a panel for a life outdoors and a technical document on murals.

Preparing a Panel for a Life Outdoors

When working with acrylics or waterborne paints on unprimed MDO plywood for interior use or panel painting, we recommend sizing with 2 coats of Gloss Medium or GAC 100 to block Support Induced Discoloration (SID). This can then be followed by GOLDEN Acrylic Gesso or a comparable acrylic ground. The resin content in the overlay of a MDO panel should help to reduce the appearance of Support Induced Discoloration (SID) by reducing the amount of water absorbed into the substrate. In our research we have not seen evidence of SID while using MDO plywood with acrylics; however, we cannot speak to the specifics of MDO from all manufacturers and we still recommend sizing as a precaution if there is concern. Testing is always recommended.

When working with oil paints on unprimed MDO, we recommend 2 coats of Fluid Matte Medium or a similar sizing in order to block oil penetration into the substrate. After allowing 24 hours dry time, this can then be primed with either an acrylic ground or an oil ground. For more detailed information on preparing a painting support for acrylics and oil paints, here is a link to our technical sheet.

Summary and Drawbacks

MDO plywood offers a lot of benefits as a painting substrate, it has a smooth surface treated to extend its life outdoors and provide enhanced durability. MDO is also structurally classified as an exterior plywood, thereby specified to be suitable for both exterior and interior use.

One thing to keep in mind about MDO; however, is that an overlay is typically used to upgrade panels that are of softwood construction. It is therefore possible for the surface of MDO to show some visual signs of reflectivity due to the varying densities of the underlying veneer. (APA, 2018) These panels may still telegraph repairs or show evidence of voids, which would need to be addressed if an artist were using MDO for exterior works. If this is a concern, it is always possible to have higher grades of plywood or even marine grade plywood overlaid to gain its benefits.

Phenol Formaldehyde Disclaimer

Since elevated levels of formaldehyde may lead to health conditions, regulations on emissions exist to limit the amount of exposure to it. To better understand these concerns, it is important to know that formaldehyde is a volatile organic compound (VOC), meaning it will vaporize or become a gas at room temperature. (APA, 2015) Wood panel products, which use phenol formaldehyde resins like MDO plywood, have been tested for emissions and have either met industrial standards or received exemptions from agencies such as U.S. Housing and Urban Development (Manufactured Home Construction and Safety Standard, CFR 3280.308), The Environmental Protection Agency’s TSCA Title VI and California Air Resources Board (CARB) Limits 8, which is considered the most strict regulation on formaldehyde emissions in the United States. (California Environmental Protection Agency, 2007) MDO products that adhere to the Voluntary Product Standard PS 1-09 for Structural Plywood put forth by APA – the Engineered Wood Association should meet these product standards and have a stamp to show compliance.

If you have any questions or comments about this article or any other paint related topic, please feel free to contact our Materials Application Department at [email protected] or by calling 800-959-6543.

References:

- APA – The Engineered Wood Association, (1997) Plywood Design Specification. Tacoma, WA: Author.

- APA – The Engineered Wood Association, (2012) Panel Design Specification. Tacoma, WA: Author.

- APA – The Engineered Wood Association, (2011) HDO/MDO Product Guide. Tacoma, WA: Author.

- APA – The Engineered Wood Association, (1995) Grades and Specifications. Tacoma, WA: Author.

- APA – The Engineered Wood Association, (2015) Formaldehyde and Engineered Wood Products. Tacoma, WA: Author.

- APA – The Engineered Wood Association, (2010) Voluntary Product Standard, PS 1-09, Structural Plywood. Tacoma, WA: Author.

- APA – The Engineered Wood Association, (2018) Personal Communication. Tacoma, WA.

- California Environmental Protection Agency – Air Resources Board. (2004). Indoor air quality guideline: Formaldehyde in the home. Sacramento, CA. Retrieved from: http://www.arb.ca.gov/research/indoor/formaldGL08-04.pdf. 16pp.

- Ebuka, D., Ezeh, E. C., Gimba, E.C., Mamza, P.A.P. (2014) Comparative Study Of Phenol Formaldehyde And Urea Formaldehyde Particleboards From Wood Waste For Sustainable Environment. International Journal of Scientific & Technology Research, Volume 3, Issue 9.

- Emery, J. A., Ph. D., APA – The Engineered Wood Association, (2002) Structural Wood Panels and Formaldehyde. Tacoma, WA. http://www.roseburg.com/UserFiles/Library/APA_Tech_Bulletin_on_Formadehyde.pdf Accessed on July 8, 2018.

- Jones, F. N., Pappas, S. P., Wicks, D. A., Wicks Jr., Zeno W. (2007) Organic Coatings: Science and Technology. Hoboken, NJ. John Wiley & Sons.

- Plenco – Plastics Engineering Company. (2018) Phenolic Novolac and Resole Resins. Retrieved from: https://com/phenolic-novolac-resol-resins.htm#2 Accessed on July 13, 2018.

- Structural Insulated Panel Association, (Accessed 7, 2018) Formaldehyde Emissions and Exemptions. Fort Lauderdale, FL. Author.

- The U.S. Consumer Product Safety Commission. (2013) An Update on Formaldehyde. Retrieved from: https://cpsc.gov/PageFiles/121919/AN%20UPDATE%20ON%20FORMALDEHYDE%20final%200113.pdf Accessed July 13, 2018

- United State Department of Labor. Occupational Saftey and Health Administration. Formaldehyde Standard (1910.1048). Washington, D.C. Retrieved from: https://osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=10075/ Accessed on July 13, 2018.

Great article! MDO is perfect for mural panels.

Hello Fritz, thank you for the feedback! It is a great option for murals!

Uyility type retailers ( home depot etc) typically dont bive a flying damn about creatives needs.

. Where does one discover mdo plywood or untreated masonite. ?

Hello Steve,

Medium Density Overlay and Medium Density Fiberboard are different products with similar abbreviations. MDO is an overlaid plywood panel, MDF (aka “Masonite”) is made from wood fibers. It should be possible, if they are not available in a store, to order MDO or Medium Density Fiberboard online from larger retailers like Lowes or Menards and pick them up at a store location. Check the websites for these stores and see if it is listed as available for pick up or delivery. A local retailer or lumber yard may also be able to order some in for you as well.

If you have any additional questions you can contact us at [email protected]

Hello Scott,

Could you please provide guidance on cradles for larger pieces of MDO? What width and overall dimensions would necessitate cradling? How would cradles be attached in a manner that would be considered archival as it relates to fine art pieces exclusively for interior spaces?

Thank you

Hello Joe –

Thank you for your question. Recently, in some of our conversations with conservators we have found that cradling is no longer seen as favorable or “archival”. The general feeling is that cradling may cause more issues than it may solve. Tension and a tendency to bend are still present in the wood, they are simply restrained and over time the wood may seek an avenue to relieve this tension. This could make its way to the surface of the plywood panel and manifest itself in the form of surface checking or cracking. It may even telegraph to the paint layers themselves. In the case of MDO and plywood in general, the cross laminated structure helps increase the dimensional stability of the panel, making it more resistant to warping, but the environment, even in an interior setting, is always a factor. What separates MDO plywood from some plywood offerings is the overlay and its phenolic resin coating, which may additionally help to reduce the risk of surface checking over time and increase the moisture resistance of the panel. We mention this upfront as a caution, since the recommendations around plywood continue to change as we learn more over time.

If you wanted to cradle an MDO panel for aesthetic or practical considerations like hanging or framing, much depends upon the width of the panel itself. Thinner panels have a tendency to warp and if you are using anything below ¾” (18mm) thickness, it should be braced in order to keep the panel in plane. We generally recommend perimeter bracing for panels that are 12” (30cm) or more, regardless of thickness. If the panel is much larger than this, we recommend perimeter bracing and cross-bracing be applied every 12” (30cm). The use of plywood cradling strips, being more dimensionally stable than solid wood strips, may help to reduce the potential of warping over time as well. Depending upon the size of the panel, either 1×2” (5x10cm) or 1×4” (5x20cm) strips could be used for the cradles. We recommend lap joints for joining the cradling, which is created as a unit separate from the panel itself. The cradle should be glued together and to the panel using a professional grade wood glue.

For more information these Just Paint articles may be helpful:

Understanding Wood Supports for Art, a Brief History

Plywood as a Substrate for Painting

Hi Scott,

Would MDO provide a good substrate for mounting linen? Do you have any resources you can point to for advice on mounting canvas or linen on panels?

Thx

Hello John,

Being a rigid support with good dimensional stability, MDO would be a great substrate for mounting linen or canvas for painting. We typically recommend using Soft Gel as an adhesive that is applied to the face of the panel. You shouldn’t have to apply any product to the back of the linen or canvas as long as you put enough gel onto the panel surface. One way to assure an even, thick application onto the surface, is to use a notched trowel. Place the linen or canvas onto the surface, lightly smooth it out with your hands. Apply plastic sheeting on top and use something like a foam or nap roller to spread out from the middle any excess material or air bubbles. Once it looks consistently smooth, you can lay another large piece of MDO or hardboard over the plastic sheeting on the face and then weigh it down. This should be allowed to dry overnight. The next day, remove the wood and the plastic from the surface and then allow the linen to dry for another day before trying to trim the edge. We have a video that demonstrates adhering paper to panel, which is essentially this same process, but with paper. It may be helpful, here is the link: Adhering Watercolor Paper to Panel Using GOLDEN Soft Gel

Please feel free to contact us at [email protected] if you have further questions.

– Scott Fischer

Hi, I have been using braced plywood painting panels for a few years and so far found no problems. As a still life painter using both heavy and soft body acrylics, plywood gives me the perfect, smoothest painting surface. I buy these panels untreated giving them three thin coats of gesso,sanding between the second and final coat to achieve a very smooth finish but with enough tooth for painting.On completion of the paintings, I apply one or two isolation coats,then up to three coats of varnish. Really pleased with plywood as a substrate,no problems

Hello David,

As a substrate, plywood has a lot of desirable qualities, many of which you highlighted in your comment. If you are finding a way to prepare plywood that works well for you and is smooth, then that is excellent, we are happy to hear you are finding success! We at GOLDEN really like Medium Density Overlay Plywood, because it has a resin coated paper overlay, which produces an exceptionally smooth surface that hides wood grain. The overlay also helps prevent the incidence of surface checking, which can occur as a result of fluctuations in the relative humidity of the environment. If you are able to maintain or control the humidity of your working or storage conditions, then surface checking should not be an issue for works done on plywood. When works are shipped for exhibition or relocated for any reason and there is a significant enough change in relative humidity, there can be a risk for the plywood to develop surface checking. We recently wrote an article on this phenomenon that can be found here:Surface Checking and Plywood, Is It a Concern?

We hope this is helpful and if you have more questions, feel free to contact us at [email protected]

`

Is the any MDO come in roll as usually it is in sheet…?

Hello Charles,

Sorry for the delay in response. Medium Density Overlay or MDO, is a form of plywood that comes with the paper overlay already attached to the surface. You could buy the MDO plywood in boards, some box hardware stores may have it in stock, but some have it available for order online for pick-up and a local hardware store might be able to order it in for you as well. We hope this answers your question. If you have additional questions about MDO you can email [email protected] or call 800-959-6543 and we would be happy to help.

Best,

Scott Fischer

Can you use a stain to seal the MDO? I have a desk that was finished with MDO but I want to stain it.

Hello Kelsey, thank you for your question. The thing to keep in mind about MDO is that it has a resin impregnated paper overlay. So in the true sense of a stain, it would not soak directly into the wood. We have not tested staining the MDO specifically, we have tested it as a viable painting substrate for easel painting or for use with murals. What we can say is that it is receptive to acrylic paints, so it could take a stain with acrylics for example, if you wanted to alter the color a bit. We have not tested it with other traditional stains. We would recommend testing first to see if that could work for you. Here is a link to technical info on staining with acrylics:Woodstaining Objects

In terms of sealing the MDO, for functional use, we would recommend finishing with something like a polyurethane to have a surface that can withstand repeated use and contact with objects. It already has a resin impregnated into the paper overlay which helps seal it from moisture, but it still might benefit from a more durable topcoat if this is a desk. Acrylics, if you were to stain with them, would not hold up as a functional topcoat on a desk for example. They are thermoplastic, if they were to get hot, they could become soft and sticky. A traditional stain may be more appropriate, but again we would recommend testing to be sure that would work for your application.

We hope this helps, if you have more questions feel free to email us at [email protected] we would be happy to discuss this further!

Warm Regards,

Scott

I have been commissioned to complete a series of 12’ x 24” murals in a historic district that requires panels on top of the original brick, I am looking for a place I can purchase primed 3/4” MDO in the Midwest. Any leads.

Hello Brant,

Thank you for your question. To get the MDO you could inquire at a local hardware store and see if they have it. If not they may be able to order it in for you. As far as primed, some manufacturers will prime the MDO, you just want to make sure it is a paintable surface. A quick google search of pre-primed MDO or Sign Painters Board comes up with quite a few option. Just make sure you follow their recommendations and it may be worth checking with them about whether or not this is good for outdoors. There is also a link on APA Plywood page for finding manufacturers: https://www.apawood.org/manufacturer-directory. This may help you find who is producing the MDO and give you more info for you search. We hope this helps! Feel free to email us at [email protected] if you have more questions.

Best,

Scott

Could I use decking screws to attach to a frame? I am hanging 10 panels of 4×8 1/2 in.

Hello Andrew, you should be able to use deck screws through MDO. It has a craft paper over lay, but it is b/c plywood. The deck screws would be a good option for the exterior. Depending upon location, you might want to seal around the screw to prevent moisture from creeping into the wood through the screw hole. Let us know if you have more questions. [email protected]

Scott