There are five key aspects directly influencing the lifespan and overall durability of an exterior mural:

- the environment in which the mural will be placed

- the paint system used

- the base surface upon which the mural will reside

- the preparation of and products directly upon the substrate’s surface

- the final protective topcoat

Usually, the environment is a factor that cannot be controlled. Nonetheless, it should be carefully considered when developing the plan of action well ahead of selecting the materials to use in a mural system. With this test, we can see the environment’s impact on each variable and determine which materials are viable options for the exterior muralist. In order to accelerate the results, we situated the test fence to face due south, at a 45-degree angle (determined as the ideal angle and direction to maximize UV exposure as per Q-Lab (1).

After enduring three seasons of ever-changing weather in Upstate New York, we pulled the panels down from the test fence and began inspecting them.

SELECTION OF PAINTS IN THE TEST

The paint system selected for this set of test panels is GOLDEN Heavy Body Acrylics; specifically, colors recommended for exterior application. These paints have been used successfully outdoors by a large number of muralists past and present. We outlined the test in a previous Just Paint Article including the set of paints representing various unique pigments recommended for exterior use, including Carbon Black, Pyrrole Red, Bismuth Vanadate Yellow, Burnt Umber, and Iridescent Copper. Multiple tests of these paints validate their approved use for exterior murals, so they serve well as set standard paint to use throughout this test. This set of different kinds of pigments additionally further our knowledge of how they age within various systems compared to the standardized test protocol.

SUBSTRATES and PRIMERS

We created a list of commonly decorated surfaces employed by muralists and prepared them to accept the paint layers.

The range of substrates in this round of testing was selected based upon the most commonly decorated surfaces employed by artists, prepared with multiple commercial coatings for the intended long and lustrous life of a given mural. Some substrate/primer systems fared better than others.

Exterior Grade Plywood: When an artist chooses to paint indirectly and later attach the mural panels to a wall, they often select Exterior-Grade Plywood as their support. After all, it’s named “exterior-grade”, right? The artist assumes this type of support is going to withstand exterior exposure. In this test, they did not fare well. The entire set of exposed panels swelled and split from water. The surface ply curled and split severely. The type of primer didn’t make any difference, as neither alkyd nor acrylic showed any signs of assisting. Our takeaway is that using this plywood for an outdoor mural will likely end in a brief, untimely demise.

Medium Density Overlay is a unique plywood often called “M.D.O.”(2) and it held up very well (as expected) in this test. This type of panel is our top suggestion for both outdoor murals and exterior signage. On one set of M.D.O. panels we sealed the board edges but not the panels’ backs. For another, we sealed edges and back with the same aluminum-pigmented exterior enamel(3). Both fared well but the unsealed backside is stained and dirty. Sealing the back and edges decreased the ability for moisture to attack the plys, and water penetration is a major contributor towards the premature failure of wooden supports.

The various types of primers used were the same for both exterior plywood and M.D.O. Along with several commercial products, we included our standard GOLDEN White Gesso. Gesso is intended for interior use, not for exterior applications. We do not recommend using our Gesso to prepare mural surfaces because it contains calcium carbonate. The concern is that acid rain can dissolve calcium carbonate potentially, creating a weak interface that could compromise the subsequent paint films. Although we did not observe any evidence of this happening, our current recommendation remains to use acrylic-based commercial exterior wood primers. We need to do an additional round of testing focusing on this question to be sure White Gesso is an acceptable primer for outdoor projects.

Cementitious Board mimics working upon brick, stucco, and other masonry wall surfaces. We used one called Hardie Board (4), which is readily available at home improvement centers. Masonry requires different primers than the ones used on the wooden panels, which are listed at the end of this article. After the primers were applied and allowed to dry, paints were directly applied to each primed panel. After the exposure testing, we noted chipping and flaking between the paint, the alkyd primer in the test, and the Hardie board. The acrylic-based primers performed better than the alkyd primer.

Another set of Hardie boards was primed like the first set was, but the paints were indirectly painted first onto a fabric material that muralists sometimes call “parachute cloth”. For the test we used a non-woven fabric called Pellon® that was painted, then attached to the test panels using our Regular Gel. In the three types of primers applied, they all held up well, even the alkyd primer did better.

Honeycomb Aluminum Panel was the final substrate used in this round of tests. The honeycomb panels (7) are very strong and accepted the “bonding primers” well. Aluminum isn’t water-sensitive, and the primers held tenaciously to the panels without issue, at least at this point in the testing. Aluminum is gaining popularity as a painting support for mural work.

TOPCOATS

Finally, we tested a range of topcoats commonly used as the final protective barrier layer for a mural. The product gamut spans from an acrylic-based masonry sealer (used as a topcoat and as a clear primer on previous test panels), GOLDEN regular MSA Varnish, GOLDEN Hard MSA Topcoat, and an automotive, two-part urethane clearcoat. We chose M.D.O. (Medium Density Overlay) plywood and an acrylic commercial house paint primer as our control surface for the set of Heavy Body paints. We did not apply isolation coats, just two coats of each topcoat (with the exception of the automotive clear coat, which was applied as one generous layer).

Automotive Urethane was the best overall protective coating. It is not surprising that an automotive clear coat held up well, as these are the clear coats used to protect vehicles around the globe. They cure via a chemical reaction (two components are mixed together and set up as opposed to a solvent evaporating out of them), making them non-porous without moisture able to pass through them. The greatest downside of these coatings is that they need to be applied by a trained, experienced technician in a proper facility. This means that a mural has to be created off-site, brought into an automotive repair shop with a spray booth, and then later attached to a wall. You’ll also need to find a willing partner, as you can imagine most car repair shops have not been approached with such a project before. We had our local shop apply the clear coat. (Thanks, Ted’s Automotive in New Berlin!). Because this is a very tight coating, urethanes (and polyurethanes) should only be used when you can entirely seal the work in order to prevent moisture from entering the panel which can cause delamination. This is also another reason why urethanes are poor choices for wall murals. Automotive clear coats are also very glossy, and sun glare can make viewing the mural difficult at times, especially for south-facing murals.

The next best topcoat in the test was GOLDEN Gloss MSA Varnish w/ UVLS, a solvent-based acrylic resin. This is our best, most practical recommendation as it can be applied by an artist or house paint company onto the finished mural. GOLDEN also makes a Mural Formula MSA Varnish intended for larger, direct-to-wall projects, where V.O.C. regulations mandate compliance with code enforcement. The varnish remained uniform and glossy with little sign of age. These products perform well and offer UV protection to slow fading of the underlying paints. It is important (as with any exterior coating) to inspect the surface regularly and apply additional layers over time to refresh the varnish layer that slowly erodes from wind and dust “sand-blasting” over the years. Usually, a fresh MSA Varnish coat should be applied about every 5 years or so.

GOLDEN Hard MSA Topcoat, on the other hand, didn’t do quite as well as its more flexible sister product. Hard MSA Topcoat developed an overall craquelure patterning, which is precisely why we moved away from recommending this product for exterior projects. The crackle doesn’t show any “cupping” or delamination yet, but it certainly doesn’t bode confidence in its durability and protective level as an exterior mural topcoat. It is still a great product for interior projects, but outside it succumbed to merciless Mother Nature.

The 100% Waterbased Acrylic Masonry Sealer used as a topcoat performed decently, but it certainly didn’t provide the level of protection of the MSA Varnish or automotive urethane. Products with a limited budget may use a product like this in lieu of the MSA Varnish, but the mural will pay the price soon enough. In three years of exposure testing, a coating like this doesn’t offer much protection and a better topcoat would be recommended to avoid early failure of an otherwise soundly constructed mural. Interestingly, various paints responded differently, with some dulling and uneven sheen of the topcoat surface. Even a crackle pattern emerged over the Burnt Umber paint on the panels. This acrylic product may be better than nothing at all on the mural, but ideally, a better product should be applied in the very near future unless the mural is meant to have a temporary lifespan.

FINAL THOUGHTS:

M.D.O. and Aluminum are excellent choices for an exterior mural, and even direct to masonry walls is fine when an appropriate primer is used to prepare it for painting. The MSA Varnish (regular and Mural Formula) still remains our top recommendation, but if you have the ability to have your mural panel professionally cleared by a local car painting shop, it’s worth the effort. This is an ongoing test that helps validate why we must be constantly testing and re-evaluating our recommendations and products. In just 3 short years, some of these test panels are ready for the GOLDEN Testing Graveyard, and some are heading back outside. As new types of materials become viable options for the muralist, we will test them accordingly. If you have an upcoming project and would like to use less common materials, please contact one of our Material & Application Specialists at 800-959-6543 or [email protected] so we can offer advice to improve your chances of creating a long-lasting exterior mural.

Primers used in Testing:

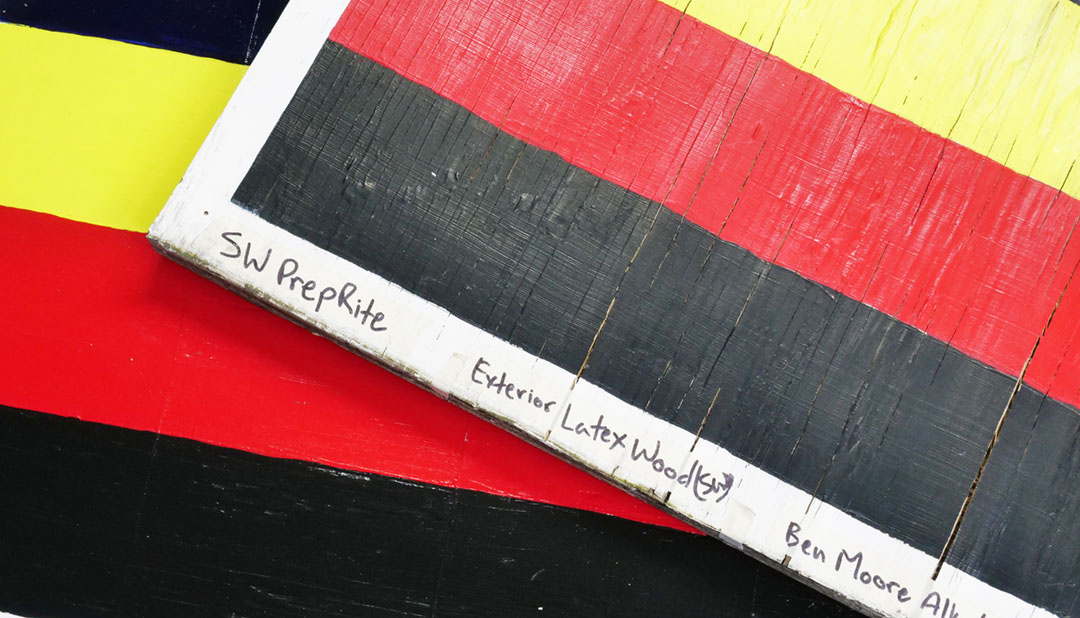

- Wood Primer Set (used on plywood panels): Sherwin Williams PrepRite® ProBlock® Interior/Exterior Latex Primer/Sealer , Sherwin Williams Exterior Latex Wood Primer, Ben Moore Super Spec® Exterior Alkyd Primer 176, Super Spec® Masonry Int./Ext. 100% Acrylic Masonry Sealer N066, GOLDEN White Gesso.

- Aluminum Primer Set (used on Aluminum panels): XIM® 400 White – X-I-M Flash-Bond ™, Sherwin Williams DTM Bonding Primer, Super Spec® Exterior Alkyd Primer 176, Super Spec® Masonry Int./Ext. 100% Acrylic Masonry Sealer N066, GOLDEN White Gesso.

- Masonry Primer Set (Used on Hardie Board panels): Super Spec® Exterior Alkyd Primer 176, Ben Moore Super Spec® Masonry Int./Ext. 100% Acrylic Masonry Sealer N066, Sherwin Williams PrepRite® ProBlock® Interior/Exterior Latex Primer/Sealer.

Cited References:

- Q-Lab Exposure Testing Parameters for Exterior Evaluation: https://q-lab.com/documents/public/2058b034-a8c2-4d8b-831b-6fe949c9053e.pdf

- Medium Density Overlay Plywood (M.D.O.) http://www.murphyplywood.com/pdfs/softwood/HDO_MDO_Product_Guides.pdf

- Rustoleum Exterior Enamel Aluminum Pigmented: https://www.rustoleum.com/product-catalog/consumer-brands/stops-rust/protective-enamel?ls=7715502&lc=Aluminum

- Hardie Board Cement & Fiber Siding Panels: https://www.jameshardie.com/products

- Pellon 910 Featherweight Sew-In Non-Woven Fabric: http://www.pellonprojects.com/products/910-sew-in-featherweight/

- GOLDEN Regular Gel: https://www.goldenpaints.com/products/medium-gels-pastes/gel

- Honeycomb Aluminum Panels: https://www.portafab.com/aluminum-honeycomb-panels.html

About Michael Townsend

View all posts by Michael Townsend -->Subscribe

Subscribe to the newsletter today!

No related Post

I did a mural on marine grade plywood, facing south in Michigan. Used several sanded Golden gesso layers on front, back and sides. Mural subject to extreme heat, cold, rain and snow. It was up for 10 years. Golden acrylic paint used. Several top coats of Golden MSA varnish gloss. There was no sign of loss of structural integrity to the substrate. There were four 4’x8’ panels. Mounted to brick wall. Used full palette of golden colors. Should have been try too coated with varnish every couple years, but was only top coated once. Chief problem was fading and chalking where top coat got thin or worn. Panels were removed after 10 years, damaged and faded areas repainted, new top coat and transferred mural inside a building. Looks like new. Not all areas needed to be repainted.

Hello, Kenneth.

Thank you so very much for providing your personal experience with using our products on a mural. The testing we did for this article was pretty aggressive, both in the angle of the test panel fences, and the sets that were primed, edge/back sealed, and painted without applying an isolation coat or varnish/topcoat. We knew by doing this method, we would learn what materials and products are likely to fail sooner than those using more stable surfaces. From your account, it sounds as though the recoating after 3+ years with additional MSA Varnish layers would have helped out, which is our experience as well. Still, 10 years in that brutal Michigan weather is a test for ANY system!

We encourage anyone that has created a mural and has been able to revisit it over the years to let us know how things are going. We are all always learning and can always improve the process for future exterior applications.

– Mike Townsend

I have found the Pellon to be a great substrate for collage (soft gel is the adhesive). I do wonder about the long term changes – the collages “stiffen” considerably over time, unmounted, as your example was.

Hello, Selena.

Thank you for comments and questions. When we prepared a roll of Pellon with 100% acrylic housepaint, then painted the color bars with Heavy Body Acrylics, the roll was stiff but still flexible without any signs of cracking. Much like woven fabrics such as cotton duck canvas, coated non-woven fabrics will retain a memory of the shape that they are in as they dry. I would assume that as long as you allow them to dry — such as stapled over a panel or table surface, directly over 4 mil thick poly plastic sheeting — the primed/cured pieces will be stiff but still flexible. I found them very easy to cut into shapes and easy to attach to the panels using Soft Gel. As long as the primers and paints are acrylic-based, they should not continue to stiffen because acrylics are relatively inert when fully dry and do not become increasing brittle as an oil-based coating does.

– Mike Townsend

Wow. Acrylics have become so exciting! I’ve been watching some of your videos which are so well explained.

Perhaps you haven’t seen my reply and question which asks if you do workshops as well?

I find that by seeing and actually participating in a new technique it sticks better.

Sincerely,

Kathleen Veronesi

Hello Kathleen.

Thank you for your kind words!

We do offer classes from time to time, but none on mural painting at this time.

We are available for help, and if you want to come up and visit, we can take some time to review and questions you may have, and play with paint!

Regards,

– Mike Townsend

I’m wanting to have artist paint indoor mural panels(various sizes), where they seamlessly look like their painted directly on walls. Was wondering if anyone could suggest what to use and also what would be best if wanting to remove them and take them to new location over time. Thanks

Hello, Michele.

Thank you for your question. I would imagine that if you want them to look painted directly onto the wall the surface of the wall would need to be at the same level as the mural panels. For example, if you used 1/2″ thick DiBond Panels (composite aluminum) you could cut holes to fit the panels within 1/2″ drywall.

– Mike Townsend