Dibond is a trade name for a type of painted aluminum composite panel made by Alcan Composites. There are other brands and types of Aluminum Composite Panels that may have a bare aluminum side or different types of coatings, which may require different surface preparation.

Dibond panels are made with two lightweight sheets of .012″ aluminum with a solid thermoplastic core. Both sides of the aluminum are coated with a polyester paint. The advantages of this type of panel are:

- Dimensional stability

- Very lightweight

- Relatively inexpensive

- Available in large sizes

- Long term durability

The current information from the Fabrication Manual from Alcan/3A Composites says that the best direct adhesion occurs after lightly scuff-sanding the painted polyester surface followed by wiping with isopropyl alcohol, and then application of properly selected paints. They also caution not to sand through the coating to the aluminum surface. Acrylics are mentioned among the list of “suitable paints”, and this suggests that many of our Acrylic Mediums, Gels, Gessoes and other waterborne acrylic products should have similar adhesion. With some higher viscosity products, however, an effect called “hold out” is a possibility, and variations in a formula could alter adhesion, so we always encourage testing. It is very important not to touch the cleaned surface with your fingers as this can leave oils that will interfere with adhesion. They also recommend always testing the paint system you are using for adhesion and suggest a cross hatch adhesion test, which is something we also often recommend. The following are adapted from both their guidelines and the testing we do:

- Apply the paint or ground and let dry for a minimum of 24 hrs. As both sides of the Dibond panel are the same, you can use the backside for testing if desired, leaving the front untouched for now.

- Over a 2” square area, using a razor blade or X-Acto knife, cut a series of parallel lines 1/8” apart. Then cut another series perpendicular to these, to form a crosshatch pattern.

- Make sure to only cut through the paint and not through the Polyester coating.

- Apply a piece of strong masking tape to the center and burnish.

- Peel the tape straight back at a 180 degree angle in one rapid movement.

- For best adhesion, no paint squares should come up.

- If any parts of the squares do come up, the test can be repeated after 3 days, 1 week, and even 2 weeks. It is not unusual for some coatings to improve in adhesion over time, depending on application and environmental conditions.

If there is need for increased adhesion, or for an exterior application, we recommend applying a suitable commercial primer to the prepared surface. These are often called “bonding primers” and are made for hard, non-porous surfaces. Two that are widely recommended are included below in our testing. While Alcan does not mention oil paints as one of the “suitable paints” for use directly on Dibond, once you have a suitable primer applied, then oil paints or an oil ground can be used.

Here is a link to the Fabrication Manual for 3A Composites’ graphics display products:

http://graphicdishttp://graphicdisplayusa.com/downloads/Dibond%20Fabrication%20Manual_May%202011.pdf

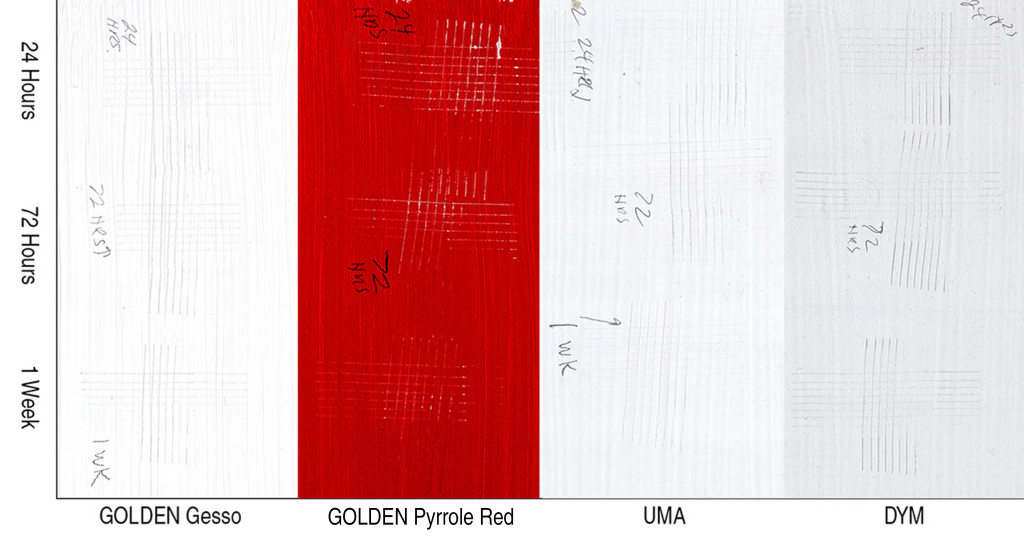

We selected four products to test for adhesion to the sanded Dibond surface:

- Sherwin Williams DTM Bonding Primer

- XIM’s UMA ( Urethane Modified Acrylic ) Bonder Primer ( white )

- Golden Artist Colors Gesso ( White )

- Golden Artist Colors Heavy Body Acrylic – Pyrrole Red

We determined that the DTM Bonding Primer and the UMA Bonder Primer would be the best two commercially available primers since both specify use on polyester coatings and other hard to coat surfaces, and we have seen successful applications with these products in the past. This does not mean that other similar primers could not work as well. PLEASE NOTE: While all the products we tested can be used for interior applications, we DO NOT recommend our Gesso for exterior use.

As a first step, we lightly sanded the polyester painted surface on a piece of Dibond using 150 grit (Fine) sandpaper making sure not to sand through to the aluminum, and then degreased it with isopropyl alcohol, wiping enough to remove all of the fine white powder from the surface.

We then divided the Dibond panel into 4 sections and applied the coatings using a white bristle brush in one relatively thin layer. The coatings were tested for adhesion using the Cross Hatch Adhesion Test at 24 hour, 3 day and 1 week intervals. We use a standardized adhesion test kit that contains a special type of tape, a burnishing tool and an 8 blade knife to make the cross hatch cut pattern, which creates 49 small squares on the test area. For the maximum adhesion, no pieces of any of the squares should come off. This is always the ideal to aim for. If any squares come off entirely, then one has complete adhesion failure. If small bits come off, retest after several days or a week has passed and see if there is improvement.

Results were good to excellent with all the products, with no squares coming off at any of the time intervals. At 24 hours our Gesso and Heavy Body Acrylic had good adhesion with some minor failure as tiny bits of product were pulled off with the tape, primarily on the subtly thicker ridges produced by the brush. Both of the commercial primers had excellent adhesion after 24 hours. At both 72 hours and one week, the Gesso showed some very minor flecks of paint still lifting, while the Heavy Body paint was now performing quite well.

It is interesting to note that while both of the bonding primers worked equally well, they have very different colors and surfaces. The DTM primer has a pale greenish gray color and is quite toothy, almost like our Acrylic Ground for Pastels, and could easily take pastel and various dry drawing media very well. The UMA primer was much smoother and a pale warm white color. However, it is important to point out that these primers were made to be covered with paint so we cannot assume there would not be changes to their color, as they are not fine art grade products. Also, whenever using commercial products, please remember that they can often change without notice, so testing and reading the company tech sheets is always strongly recommended.

Finally, while a simple light sanding and degreasing with alcohol allowed painting directly on Dibond with our Heavy Body paint, and this should be true for our other acrylic paint lines and products, our test obviously did not cover all the possible materials, applications, and environments you might be working in. So it is always important to test. If for any reason you need increased adhesion, then the bonding primers we tested could be an alternative to look into.

HI Scott,

Thank you for this excellent survey of your findings! I’m thinking that I’ll use the UMA primer and then one or two coats of Golden gesso to assure a white ground that won’t change. Does that sound right/necessary? Thanks.

Jill Nathanson

Hi Jill. You are most welcome! Applying a coat or two of our Gesso over the UMA primer sounds like a good idea. The only other thing would involve creating other types of painting grounds over the Gesso, if your painting method might require a surface with more or less absorbency.

Thanks for this much needed “official” article about Dibond! Because I sometimes like to keep the reflective, brushed aluminum showing through, I have used a “primer” composed of Matte Medium and GAC-200 (“Improves Adhesion to Non-Porous Surfaces”) with good results. I have found that if I let this dry for at least 48 hours the adhesion is excellent.

Additional Tip (from experience): Make sure the aluminum composite panel is the kind with the polyester coating (not raw aluminum!) and don’t sand all the way through it (as mentioned above).

I love GAC-200 as an intercoat, but I would NOT use it as a sealer or primer. Run your GAC-200 under slightly warm water and see what happens. There are much better products out there. Createx Transparent Sealer is the best option for waterbased, and Glisten PC is the best for urethane. GAC-200 and Novacolor 235 make fantastic intercoats.

If you are painting on bare metal (not dibond with its layers of plastic outer coating), you should be using an adhesion promoter for steel, copper, etc. Even with aluminum I will throw one on sometimes for extra adhesion.

Hi James,….We would also agree that there are most likely better products to use as metal and aluminum primers than our GAC 200. It was not designed for this purpose. Can you tell us more about what you have seen when you run a fully dry and cured film of GAC 200 under warm running water? We would not expect any changes to occur unless the film were held under water for a length of time, as it would become blanched due to moisture absorbing into the film, but then this would happen with any fine art grade water borne acrylic film as they remain micro porous to air and water vapor. But, simply running under warm water should not produce any changes to the film, unless it was not completely dry and cured. GAC 200 must cure at 70 degrees F or higher to produce a fully cured film. And we agree that some kind of specialized aluminum primer is best for aluminum. Mark Golden addresses this and more in his article on Painting on Metal. We have theorized that Incralac may work well as a kind of translucent primer for aluminum, as it will also reduce any incidence of oxidation, which can still form under many types of films on aluminum and at least theoretically, might cause delamination over time.

Great article by Scott!

All my acrylic paintings in the past 4-5 years have been on Aluminum Composite Panels preparing the surface this way.

2 years ago I started working with watercolors and treating the aluminum with Absorbent Ground after the gesso and industrial primer (I’ve been using Sherwin Williams – Extreme Bond Primer a relatively new product) and then doing QoR Watercolors on that. I spray 2 coats of Archival Varnish to protect the watercolors and free them from the need to be under glass. Really great results.

Roy Kinzer

Thanks for your kind comments about my article, Jill, Andrew and Roy!

We do not have any long term testing of GAC 200 and Matte Medium on brushed aluminum, and the important thing here is that this coating will not stop the aluminum from tarnishing over time. There are some coatings that apparently will help with this. Again, we do not have testing with these products to cannot recommend with full assurance. We suspect that Incralac, a coating used on non-ferrous metals like bronze and brass to protect and slow down or block oxidatiion, can also be used on aluminum. They are translucent but may yellow over time.

Roy,…thanks for the information about your method of doing watercolors on Absorbent Ground on Aluminum!! Very Cool!

I do want to add that we have seen good adhesion of our Fluid Matte Medium on lightly sanded aluminum and that we suspect adding in some GAC 200 could assist with adhesion. And I want to retract my mention of yellowing with the Incralac as this was only conjecture. Most translucent coatings do have changes over time, so we wanted to make sure that if total clarity was important, this might not be a guarantee. Incralac does contain UV inhibitors which we know can assist with maintaining more clarity in acrylic films over time.

I should clarify that the “brushed aluminum” color I referred to is actually Dibond’s “brushed silver” metallic color and it is still protected by the baked laquered (polyester) coating, so I don’t think there should be an issue with tarnishing. The paint should adhere as well to this as to any of the other colors of coated Dibond panels.

” this coating will not stop the aluminum from tarnishing over time”

I am perplexed by this question. Bare aluminum will not tarnish if you use materials that are designed for it. This includes waterbased sealers and paints that have been formulated for painting on metal.

What is very odd to me is that this entire discussion (which I guess is a valuable contribution in a sense) is being conducted without so much as a single reference to a vast industry that specializes in painting on metal.

That industry, of course, is the automotive industry. Cars are basically painted aluminum or steel, exposed to the sun for years in a variety of temperatures, humidity settings, etc. Engines put out extreme heat, as does the sun in places like Arizona.

Yet, there is nary a reference to automotive painting technique, to books, to videos, or to experts. Madness. Anyone who has studied automotive painting techniques (particularly custom painting ones) will know that it is common to paint over ground metal aluminum panels with waterbased paints, followed by some form of clear coat for protection. Createx Acrylics makes fantastic sealers for preparing metal surfaces, but they are often not required for applications on aluminum. Craig Fraser, for instance, just paints directly on the aluminum surface.

There are urethane primers, polyester primers, acrylic waterbased sealers available for use on metal. Common paint choices include solvent-based urethane (e.g., house of kolor) and waterbased (e.g., Createx AutoAir or Wicked).

Since cars have to hold up over a much greater temperature range than indoor art, any technique used by automotive painters is safe for artists. I recommend that you direct your readers to check out some videos from this industry. After all, these people pay their mortgages based on whether or not their paint jobs hold up to extreme conditions.

As for dibond, my own recommendation (after taking many classes with custom painting experts like Cory St Clair) is to scuff the surface and either paint directly on it (with airbrushes and relatively light layers of paint), or if you want thicker paint layers to spray apply a coat of Createx Sealer or some other primer. Sand that when you are done with 600 grit. Properly done, a spray application results in better adhesion than applying a primer with a brush. If you can’t manage to learn proper spray gun technique, well… you might want to reconsider painting on metal surfaces. Failing to use best practices is unprofessional.

Hi James,

Thanks for your comments. I am not sure where your quote is from …” this coating will not stop the aluminum from tarnishing over time”,..as it is not from this article. But, we have made similar suggestions to artists in the past if they want to use a translucent acrylic ground directly on aluminum. We have seen pretty good adhesion directly on roughed up or sanded and degreased aluminum with our paints and mediums, however, our best advice for aluminum, is to use a dedicated aluminum primer that contains components for reducing oxidation.

“Bare” or raw aluminum comes with a microscopic oxide on the surface as it oxidizes almost immediately. While we do not have testing to prove that aluminum will continue to oxidize under certain coatings, we suspect that it could. We also suspect that over time, the oxide formation might,.,.and I stress might,..have some effect on adhesion of come coatings. We prefer to err on the side of caution with this.

We refer to the auto industry routinely in answers to questions regarding painting on metals. We often suggest auto body primers and auto body clear coats, and in fact this is always our advice for using our products directly on metal for any exterior use, in particular. This short article was very specifically about painting on Dibond, not directly on raw metal surfaces so was not the place to discuss the issues you reference.

If you find that certain products work well for you then we would always suggest using those products. Fine art use often requires some different preparations and recommendations that dovetail better with an artists particular ways of working.

Our experience does not back up that a spray on coating will always have better adhesion than a brushed on coating. And as noted in this article, we did not test all primers available, but found the ones we did test worked as noted. You will see that we also found our acrylic paints adhered quite well directly on the sanded polyester paint surface. For more details about painting directly on metals and specifically on aluminum, I would refer you to Mark Golden’s article “Painting on Metal”…Painting on Metal: An Introduction, by Mark Golden: https://justpaint.org/painting-on-metal-an-introduction/

Forgive me if I misunderstood, but your comment in this thread was about ‘brushed aluminum’. That means, to me, aluminum that has been given a surface texture but without a polymer coating. Hence, that would be bare aluminum unless it you mean an anodized ‘brushed’ surface.

“Our experience does not back up that a spray on coating will always have better adhesion than a brushed on coating”

That’s cute. It is also not convincing. How many quality assurance teams do you have running around the country making sure that your products are not peeling?

Well, the auto manufacturers and paint companies like PPG have massive quality assurance programs. They have teams of people who go around cities looking at car finishes. The same is true of industrial paint companies like GCI.

If brushed-on coatings are competitive with spray or powder coatings, why don’t we see industrial manufacturers using brushes? Brushes are actually easier to control, they waste far less material than spray guns, and they don’t require the heating equipment that powder coating does.

They don’t use brushes because the adhesion and consistency of film thickness aren’t as good as with spray or (better yet) powder coating techniques. If brush application was leastwise competitive, you’d see at least a few industries using it.

By all means, continue to do tests for the use of fine arts materials on hard surfaces. Golden is an awesome company that makes top notch fine arts paints. However, the entire art industry has even a fraction of the QA support that the industrial and automotive coating industries can summon up. I shudder to think of fine artists spending hours on fine art only to find that their work is separating from the support due to poor technique or choice of materials.

PS: prices on dibond for artists are unreal. Just go to a building supply store, buy some and cut it with a knife. Easy to parcel up.

Hi James,

The discussion did take a turn into the issue of painting directly onto aluminum, although the main thrust of the article was painting on the polyester paint coating on Dibond. And while I did not mention “brushed aluminum” specifically, I did mean some kind of abrading of the surface to create more surface area contact with a coating, for the purpose of increased adhesion. This is something that the coatings industry at large suggests routinely with many kinds of coatings applications. What we try to do is flesh out a ‘best practice’ with what we know to date, which can often include unknowns.

I did not mean to reference anodized aluminum.

As for spray vs brush on coatings, we are aware of some situations where brushed on applications can create better adhesion simply due to the physical action of the brush on a surface which can create more surface area contact, and where a spray on coating on certain surfaces may have less surface area contact. Much can depend on the expertise of the user. As for why the industrial sector uses spray applications over brushing applications, I think it is pretty clear that spraying is much more efficient, especially for 3-D objects. It is hard for me to imagine a brush on application of an auto body. I think you are exactly right about the fact that spray application will produce a more consistent and even coating if done right, and there are many situations where we do suggest spray applications for the best results.

We do not have quality assurance teams “running around the country” making sure our products are not peeling. We do, however, assist thousands of artists every year with issues like this and more via our tech support team. We have visited artists studios to investigate situations where anomalies or other issues may be present, and we pride ourselves on being unique in the industry in the amount of testing and research we do. We answer thousands of questions every year helping artists to make better decisions with their materials. While we may not be running around the country, we are regularly fielding questions, looking at photos of work, testing, sharing our information, and helping artists manage this often complex landscape. Whenever fine art grade products are combined with other kinds of products, there can be variables at play that create questions and more risk.

What we do have here at Golden Artist Colors, is intensive and constant testing and research on our products and other products to insure quality and consistency and to increase our knowledge base about the use of fine art grade materials for artists. Whenever we do not know something, we say it. And, we do regularly reference other industries that know more than we do about specific coatings applications. How that dovetails into fine art use, is not always clear, and again, we think it is important to state this. Artists have and will always use materials and methods that might have significant unknown variables. Our preference is to suggest more known materials and methods, while also respecting the experimental nature of art making.

I think if you read Mark Golden’s piece that I suggested previously, you will see that the issue is complex and not enough known to be so definitive about fine art use of aluminum as a substrate. Here is that link again:

Painting on Metal: An Introduction, by Mark Golden: https://justpaint.org/painting-on-metal-an-introduction/

We typically offer caveats to our suggestions about painting on metal in general, and we do routinely reference both the auto industry and the industrial coatings industry at large, and suggest that one must manage the overall risk management of the situation within the fine art applications scenario. In the end it is all risk management as even auto coatings and industrial coatings will fail at some point in time. There are many variables at play.

If you have more questions, please feel free to contact us at: [email protected]

I just learned that Dibond does make a “brushed aluminum” panel, but like its other products, this has a polyester coating that is clear. So one can have a brushed aluminum effect without painting on actual raw aluminum. And of course with Dibond, the goal is to scuff the polyester and not break through to actually scuffing the metal itself.

For reference see:

http://www.tri-dee.com/Dibond%20Aluminium%20Composite%20Panels.htm

“3A Composites USA Inc. is pleased to announce the introduction of our newest Dibond material ,brushed aluminum finish. This new composites material finish has polyester clear-coat applied over the brushed aluminum finish. Protective masking will come standard, applied to the brushed aluminum side of sheet”

Thanks you for the information and testing. This is the first time I have heard of Dibond. I think I will have to try it out.

Any experiments with oil paint?

Hi Dean,

You can most certainly use oil paints, and while there will probably be good adhesion directly to lightly sanded aluminum, we would recommend applying one of the primers we tested on the sanded polyester paint, and then the oil ground or gesso or other painting ground of your choice that will be suitable for oil adhesion. If you wanted a translucent ground, we have recommended using our Fluid Matte Medium directly on sanded raw aluminum.

I do mention oil paints briefly above, in my article. Here is the segment:

While Alcan does not mention oil paints as one of the “suitable paints” for use directly on Dibond, once you have a suitable primer applied, then oil paints or an oil ground can be used.”

“If you wanted a translucent ground, we have recommended using our Fluid Matte Medium directly on sanded raw aluminum”

This is not good advice. On bare aluminum there are much better (stronger, more adhesion) products out there. Golden Fluid Matte medium versus Createx Transparent sealer is not a competition. The latter is much stronger, with better adhesion. Do a scratch test or put them in high temperatures to see the difference.

As I said in my other post, as soon as you are painting on metal you are in the realm of automotive painting. The auto industry is FAR better than you guys at painting on metal surfaces. If you are not using their techniques and materials, you are not using best practices. If you want to paint on metal you should be following their techniques, and I challenge you to find me a single automotive painter in the world who would start a job by using an acrylic medium as a sealer or primer.

As for oils, you can also consider the use of a proper industrial alkyd base coat over either the plastic outer layer of the dibond, or over a primed raw metal panel. Gillespie Coatings makes some great industrial strength alkyds that are used by the military, among others. The other big paint companies also have alkyd primers and the like. These can be brush applied, but spray application is stronger. After letting it dry, sand it with 600 to get enough tooth for an oil painting layer to stick.

You should not be

Hi James,

Again, I am not sure exactly where this quote came from, as it is not in this article, but it is something we have mentioned to artists over the years.

Our advice to use our Fluid Matte Medium directly on lightly sanded aluminum as a translucent ground, is one that we have made on occasion when an artist wants to use our products on aluminum and is either painting with acrylic or oil. The Fluid Matte Medium provides a light tooth that allows better adhesion with oil paints. It is certainly most likely that there are other products that will have better adhesion, but the Fluid Matte Medium on sanded aluminum will have good adhesion.

Again, if you or other artists find materials you like and that work well, by all means use them. And we always recommend testing to learn more about the specific adhesion and visual effects of any products you might use.We are not sure what kind of “high temperatures” you are referring to here, but we would not recommend using our products or any acrylic products ( I assume Createx is an acrylic dispersion product ),…as above 300 degrees F acrylic films will begin to degrade.

All fine art grade acrylics will be relatively soft and so of course they can be easily scratched. For the best testing of adhesion we always recommend the Cross Hatch Adhesion Test. Here is a good article on testing…Testing for Your Application https://justpaint.org/testing-for-your-application/

And yes, again, we do regularly recommend automotive primers and clear coats when appropriate. We would still recommend a dedicated aluminum primer over other types of metal primers if using aluminum as a substrate and if concerned with longevity. These types of primers may be alkyds or urethanes. Finally, I would recommend reading Mark Golden’s article on painting on metal and aluminum here: Painting on Metal: An Introduction, by Mark Golden: https://justpaint.org/painting-on-metal-an-introduction/

Thank you for the article. Appreciate that there might be a more rigid surface than canvas or paper (board) and lighter than masonite that might handle size.

Just checking to see if I am understanding your opinion , correctly. The commercial primers bonded better , but there are concerns about consistency and content of the material. Would these concerns extend to eventual changes in the painting ? Secondly , it sounded to me like you thought golden heavy body held up better then the acrylic dispersion ground.

I want to use Golden gesso / acrylic ground and then Golden paints and not work with the commercial primers would it be less strong than starting with the commercial primer ?

Thanks in advance !

Hi King! There will always be concerns, and the reality that products may change formulas without notice to the public, and that we have no control over that. This is why we mention it, and why we always recommend testing. We would doubt that these changes would translate into eventual changes in the painting, but this can only be an educated guess.

There was a very subtle difference in this test between our Heavy Body Acrylic and our Gesso at 72 hours. I would not think this tiny difference would make any significant difference in the adhesion, long term.

From what I saw in this testing, and this is what I state in my article,….the commercial primers had the best adhesion more quickly, and so we think if you want that increased adhesion, then go with those products, but that the Gesso and HB paint performed very good too. While we can rarely make guarantees, it does not appear that you should have any problems with using our Gesso, following our best recommendations for preparing the surface.

Hi Scott, thank you for this very useful article!

Do you reckon OMS would make for a good alternative to isopropyl alcohol during the cleaning process of the polyester surface (prior to gessoing)?

Hi Dan,

You are most welcome! Much depends on what you are degreasing and for metals, stronger solvents like acetone or mineral spirits are often recommended, but for this purpose, we think either rubbing alcohol ( typically 70% ) or stronger 99% isopropanol should be fine, and much safer than acetone or even the OMS. It evaporates fast and should remove any small amounts of oils or other surface contaminants.

thanks for this info. What would u advise for adhering raw (acrylic primed) linen (or arches oil paper) to Dibond? Are the commercial products acidic so apply coats of GAC or acrylic gesso before the linen then gloss gel medium to adhere the linen or paper? Then 2thin coats of gesso over the raw linen (does the linen also need a SID GAC layer)? I’m thinking of using fine lightweight linen. Any tips for getting out air bubbles without squeezing out of too much acrylic gel? Thanks

Hello JB,

We generally recommend using our Soft Gels to adhere paper or canvas to panel. The commercial primers should not be acidic and so you can simply prep the Dibond as I recommend and go right to adhering the paper or linen onto that surface. If you are painting with acrylics or oils we do recommend that you size the linen with a coat or two of our Polymer Medium to block oil from getting into the linen, or to block SID from getting into any more translucent acrylic films. You can then apply our Gesso over the Polymer Medium.

Lightweight linen might be tricky in terms of some of the Gel getting through to the front as you press it down into the wet Gel. It may squish up through the more open weave. A thin, brushed on coat of Soft Gel ( Gloss) on one side of the Linen allowed to dry before gluing down can help. Make sure to secure the linen on a board, stapled all around so it will shrink evenly and not deform when applying the Gel. Just in case make sure you have a sheet of polyethylene plastic under the linen. Then remove when dry. Lay that side down into the wet Gel.

A printmakers brayer can work well to smooth out the linen and the wet Gel underneath. Here is a link to a video showing a simple method for adhering watercolor paper to panel:

Adhering Watercolor Paper to Panel: http://www.youtube.com/user/GoldenPaints

Hi Scott, any thoughts on storing Dibond? Headed to a residency and have a stack of the stuff that I’ll paint with acrylics. Then need will need to drive 14 hours home. Temporary then permanent storage plan needed…

Hi Joelle,

It has less to do with storing the Dibond and much more to do with storing and handling any surface painted with fine art grade acrylics. The main issue has to do with the relative softness of acrylic films and that they will get softer at warmer temperatures ( thermo plastic ) and then potentially stick to other surfaces and also become ferrotyped. The best way to store any acrylic painting is with nothing touching the surface. This is not always possible, but generally accomplished with various kinds of collars around the painting to maintain some space in between the painted surface and any other surface. For panels like Dibond you may need to create some kind of rack system where they are standing upright to reduce pressure, and then use silicone release paper as your slip sheets.

Here is a good article for you: https://justpaint.org/safe-handling-and-transportation-of-acrylic-paintings/

I hope this is helpful, and best of luck at the residency!

Hi Scott,

This has been a topic of interest for me since I started painting on ACP a couple of years ago. Essentially my conclusion is that no one really knows what the long term results of artistic painting on aluminium will be. Opinions on the topic are merely educated guesses. In another 200 years maybe we’ll have some definitive answers.

Just wondering, you mention potential corrosion under paint applied to aluminium. Do you have any information on how or why the common white polyester coating on ACM itself offers protection from this corrosion? There seems to be a common assumption that the polyester layer on the aluminium is safe yet coatings applied by artists may not not be but I have never been able to find an explanation for this.

The obvious issue with the idea of using a commercial non-artistic primer is that they are presumably not formulated with an archival result in mind. Who’s to say what reaction they may have with the artistic paint applied on top and that this isn’t potentially more of an issue than the possible corrosion of aluminium prepared with out such a primer? PY32 is used as an anti-corrosive primer in industry and is also available as an artists oil colour. I have used this on raw sanded aluminium and it is easy to add a dry ingredient to give extra tooth. You may want to look into it.

Hello Peter,

It is true that many conclusions are educated guesses. It becomes more an issue of the quality of the testing done on the particular issue. With oil paints, for instance, we are finding out that testing virtually stopped a long time ago with the assumption that since it was such an old medium, there was nothing more to learn. Turns out not to be so. On to your questions and concerns:

PY32 is a pigment – strontium chromate, that is a very opaque yellow color often used in various binders to make metal primers (primarily zinc, magnesium and aluminum ) that inhibit oxidation. It is also used in pyrotechnics as it is a strong oxidizer. Separate from the pigment, the particular primer’s properties would largely be dictated by the specific resin used for the binder. Urethanes, Alkyds and Epoxies are the most likely types of resins use, and each group has within it many types. We are familiar with chromate based metal primers, and these could, and are often used on aluminum for industrial use. But, we would generally not recommend using a fine art grade oil paint as a primer on metal as oil films would not have good adhesion with acrylic paints on top, and if you are painting with oils, then you would be limited to only using subsequent oil films that have a similar level of “fat-ness” or ratio of oil in the film. You must adhere to the fat over lean rule for a sound oil painting. There is a very good reason why oil films are not used in industry or for exterior applications – they do not perform well. The term “oil based” is sometimes seen on containers in hardware stores, but these are always alkyds, which are synthesized from various kinds of vegetable oils and more related to polyesters.

You are certainly correct that the verdict is out on long term results of fine art painting on aluminum, especially since there are so many different kinds of aluminum and many different coatings and primers used. Along with various kinds of paints. Many variables. We do not have any test data on the veracity of polyester coatings on aluminum in terms of how well they perform over time. We suspect that the combination would last longer than any cotton canvas, which will lose half its tensile strength within 50 years or so and eventually become quite weakened over time. There is some literature on polyester powder coatings you can find online, but we have no test data.

We know that polyesters are very stable molecules. We know that the testing we did showed very good adhesion of our paints and Gesso to the sanded Polyester coating. We would expect no adverse interactions between the coatings. We infer that the more industry controlled and applied polyester coating may have advantages over an individual applying some other kind of coating to some unknown type of aluminum. We have suggested in some cases that a product called Incralac (which is a type of acrylic ), could be used as a kind of translucent primer on aluminum that would also inhibit oxidation. It is known for this property and recommended for use on copper, bronze and brass on exterior objects. But, once again, we have no test data other than adhesion testing of our paints to the Incralac, which is quite good.

It is important to point out that most paintings painted today, will have to wait many decades to see exactly how they will hold up. Oil paintings can be suspect as there is still so much we do not know or understand about oil films, and the very specific best practices for “fat over lean” are often not applied. We know more about acrylic films even though they are much younger as materials for artists. The category of “commercial coatings” does not preclude stability or long lasting qualities. And quite a bit of good, mostly harsh exterior testing, is usually done on these materials. The main issue with a lot of these materials is that they are typically hard and rigid films for use on functional surfaces. So best not used on flexible substrates like canvas.

We feel pretty confident with our acrylic paints on top of certain types of commercial primers, such as specific types of alkyds and urethanes or polyesters,… assuming adhesion testing is positive and the specific product states clearly that water borne acrylic or “latex” coatings can be used on top. The companies making these coatings have all testing for this kind of application.

In the end, though, you are correct to question all of these conclusions, and as always, we proceed with some element of risk no matter what materials we use.

Here is a good article by Mark Golden about painting on metal, focusing on aluminum:

Painting on Metal: An Introduction, by Mark Golden: https://justpaint.org/painting-on-metal-an-introduction/

Hi!

Can you afix a PRE PRIMED linen ( Lead) to a honeycomb panel (thicker than DiBond and lighter)

And how would you do it in a larger size- say 40″ X 60″

Hi Sharon,

Yes, this is possible. As with any new procedure, testing and practice will be important for success. Linen is particularly moisture sensitive and tends to shrink and then expand more than cotton canvas, so this is a factor one must learn to deal with. If it is pre-primed with a lead white ground this may help mitigate this issue. This may also cause the Gel to take longer to dry due to less air flow. Again, test first to learn more how it reacts. Prepare the surface of the Dibond as noted in our article, and then use our Soft Gel in the sheen you prefer. The Gloss will work fine and unless you think some of the Gel might be visible, there is no need to use Matte or Semi-gloss sheens.

Here is a link to a video showing a method for adhering watercolor paper to a panel and this should give you some starting points for this application:

Adhering Watercolor Paper to Panel: http://www.youtube.com/user/GoldenPaints

And here is more information about using our Gels and Mediums as adhesives: Gels and Mediums as Adhesives: http://www.youtube.com/goldenpaints#p/a/u/0/PCPO-VJQB1s

Larger sized canvases will be more of a challenge for all the reasons you can imagine, and so having extra hands to help will be a good idea. Using a notched trowel to more quickly spread the Soft Gel on the prepared panel surface works well, as it allows for a quick and even application. Drying of the Gel before you get the canvas or linen on the surface can be an issue, but the notched trowel will help significantly. This is a common tool found at hardware stores and used to apply construction adhesives, and other materials. You may find that applying the Soft Gel in sections, and carefully pressing the linen to the freshly applied Gel will be a good way to proceed, but again, begin by testing and practicing on smaller pieces and working your way up to the larger size.

I hope this helps, and if you have any more questions don’t hesitate to email us at [email protected]

Great article! I’m starting to prepare a bunch of Dibond panels for my acrylic paintings using the DTM Bonding Primer followed by Golden Gesso.

I’m wondering if you guys have any thoughts on aluminum exposed during filing of the edges of the panels, to make them safer to handle after cutting. I find this necessary to work with them comfortably but it can expose up to 1mm of aluminum. Do you think covering this with the DTM Primer will be safe? Probably not…!

Hi Matthew,

Thank you! For raw aluminum, we think the DTM primer would be ok, and because there is no long term testing, we cannot say for how long it would be ok. Probably for decades and perhaps longer. Aluminum comes in many varieties with a large range of properties, so there are built in unknowns here. We do know of a product called Incralac which is used to reduce oxidation of non-ferrous metals. It is actually a type of acrylic with additives. It it often used on bronze, copper and brass objects, and it can also be used on aluminum. You might find a DTM primer that has similar properties, or if concerned, apply a coat of Incralac and then perhaps the DTM over that. We suspect the adhesion would be good. You can find Incralac for sale via a number of conservation product companies if you google “Incralac”. It comes in waterborne and solvent borne formulas.

Here is more information about working on aluminum: Painting on Metal: An Introduction: https://justpaint.org/painting-on-metal-an-introduction/

Thank you for the information!

Am I understanding the concern to be that even when covered with DTM primer the raw aluminum portions will continue to oxidize, which will eventually lead to some kind of film failure of the primer and whatever I’ve painted on top of that? Would the oxidation occur even with a final presumably non-porous varnish layer atop the completed painting?

It might be easier for me to trim down the rough edges with a another, cleaner cut, and then perhaps round them slightly. I found some info about that here:

https://signs101.com/threads/cutting-aluminum-composite-dibond.121190/

But I appreciate the suggestion of Incralac! I will investigate further…

Thank you!

Scott,

Thanks for this article. I just found it while researching dibond for pastel use. Have you specifically tested your Golden Acrylic Ground for Pastels on dibond? I know you suggested that Sherwin Williams DTM would be a good option for pastels, but I’d be more comfortable working on the Golden Ground.

Hello Kristin,

Sorry for the delay in our response. We have not specifically tested the Pastel Ground directly on the Dibond. Adhesion would be dependent upon whether or not the aluminum composite panel had a coating or was un-coated. If you were interested in doing this, it should adhere well if you followed the surface preparation as outlined in this article. A raw Dibond panel may require the use of a DTM (Direct to Metal) to achieve strong adhesion of the acrylic ground, like our paints and gesso that where used in the testing for this article. You could certainly apply the Pastel Ground over the gesso or the DTM as well if you preferred the toothy quality that the Pastel Ground provides. We hope this helps answer your question. If you have additional questions let us know our email is [email protected]

Scott Fischer

Hi, thanks for the article.

In Australia, there are several ACM products (like Dibond, but manufactured elsewhere), variously coated in “polyester paints” such as fluoropolymer resins (FEVE), polyvinylidene fluoride (PVDF) or sometimes just “polyester”.

Two questions:

1. Are all of these coatings just different forms of polyester, and therefore likely to behave fairly much the same if overpainted with an acrylic dispersion ground – an artist quality acrylic ‘gesso’?

Of course I would follow the scuffing/alcohol regime referred to above.

2. They are available in various types: matte, gloss, high gloss. Presumably matte would be best, as we are going to scuff it up anyway. What do you think?

Thanks

Hi Geoff,

You are most welcome. While we suspect that these various polyester paints are similar, we cannot verify that they are exactly the same from company to company. I would agree with you that it is likely that they are similar enough that they would all behave the same if prepped and primed as I outlined in my article. And yes, I would go with the matte, just to be safe!

Thanks

I love to work with ink on the aluminium sheet and i need a smooth surface what do you suggest to prime the panel with?

Hello Golpira,

You may be able to use some types of inks directly on the suggested primers. Or, for a very smooth surface, you could try applying multiple, thin scraped on layers of our Molding Paste, as we describe here:

Creating a Smooth Surface Using Molding Paste: https://www.youtube.com/watch?v=NP3br4sx7Uo

Ultimately, you will need to experiment to find the surface that works best for you. I would start with the primer surface, and if needing something smoother, try either sanding the primer itself, or use the Molding Paste method. You may find that wet sanding works well. We also have a product called Sandable Hard Gesso, which can be much more easily sanded due to its extra hardness:

https://www.goldenpaints.com/technicalinfo/technicalinfo_sandable

Best of luck with your work!

I have been using this approach for a while on the DIBOND panels I use. But, now I would like to adhere some of the new polyester (primed) cloths to the DIBOND panel. Caravaggio makes a good one — one surface (the back) is polyester, the other is primed.

My issue is finding an appropriate adhesive that will stay on the DIBOND panel, and hopefully not become so acidic that it would eventually cause deterioration.

One approach might be to use the marine bonding agent, then gesso then an adhesive to mount the cloth. That’s a lot of prep work. I’m wondering though if there might be an appropriate adhesive that could go directly onto the DIBOND and to the polyester cloth. It has to be cold-mounted (ie: no heat).

Any suggestions? Thank you!

Hi Forrest,

A number of our Gel Mediums can work very well to adhere canvas to a panel, including to a properly prepared Dibond panel. There is no worry about acids in acrylics. And polyester canvas should not be affected even if there was some acidified material in contact. We would expect that our acrylic paints and mediums should adhere well to the DTM bonding primers, but it would be a good idea to test this. Our Soft Gels or Regular Gels can work for this and it’s a good idea to also brush apply a thin coat to both surfaces and let dry, before applying a layer of Gel to glue the canvas to the surface. This insures good acrylic to acrylic contact. Here is a similar method in this video: Adhering Watercolor Paper to Panel: http://www.youtube.com/user/GoldenPaints

Hi to everyone,

I would like to ask if someone knows any bonding primer that can be found in Europe. Neither Sherwin Williams DTM Bonding Primer nor XIM’s UMA is available here. I want to prepare Dibond Mirror finish aluminum panel

Thank you very much!

Hello Francis,

thank you for reaching out! We have not tested other European products, but would trust that there are good quality products out there as well. If you search for ‘adhesion promoting metal primers’ or ‘aluminum primers’ in your language, you should find suitable products.

Here is an example for a German product: https://alpina-farben.de/produkt/alpina-spezial-haftgrund

Feel free to write us an email to [email protected] or follow up here, if you have more questions.

Best, Mirjam

Hi,

Unfortunately the Sherwin Williams DTM Bonding Primer and XIM’s UMA are not available in Europe. I would like to ask if anybody knows any alternative bonding primer. I have to use the mirror finish aluminum panels and the acrylic gesso does not stick well.

Kind Regards,

Francis

Hi,

Firstly, thank you for such an informative and thorough article!

I am about to paint a large mural (1200 square feet / 112 square meter) on ACM panels and then install it onto the side of a building’s exterior. I already intend to sand, prime and later seal the finished painting so your article has been very helpful in planning this.

As I am sourcing all of the materials myself I have been researching local distributors of ACM substrate panels and am interested in some of the alternatives to diBond. I have found a few brands that stack up to 3A for quality, some of which come with varied thicknesses for the aluminum skins. As it is only the painted polyester surface that is being roughed up to prime, do you feel that thinner aluminum skins would work just as well?

eg. 3mm dibond has 0.012″ skins (0.3mm)

I have found 3mm ACM with 0.008″ skins (0.2mm) OR 0.006″ skins (0.15mm)

The overall panel thickness remains 3mm, and since they will be mounted directly onto a concrete wall the rigidity is not an issue for me. I feel that as long as the painted surface is scuffed without revealing the aluminum underneath it should work just as effectively.

Any thoughts or comments?

Thanks!

Hello Simmagedesigns,

You are most welcome!

We do not have testing of different types of ACM panels with different thicknesses of aluminum so cannot offer any information in this regard. It sounds likely that thinner aluminum could be ok. But again, we would need to see some kind of long term testing to feel completely comfortable with saying anything definitive. I would have to agree with you that it certainly seems likely that you would be good with the slightly thinner aluminum skin. Best of luck with your mural! And if you have not seen our exterior mural information and related links, here it is for you, along with information about out Mural Paints and mural formula MSA Varnish which you can order directly from our PaintWorks site:

Mural Paints: https://www.goldenpaintworks.com/gpw-mural-paints/

Exterior Murals: http://www.goldenpaints.com/technicalinfo_murals

Mural Resource Guide: http://www.goldenpaints.com/technicalinfo_muralresources

Selecting the Best Exterior Mural Pigments: https://www.justpaint.org/selecting-the-best-exterior-mural-pigments/

Estimating Square Foot Coverage for Products: https://www.justpaint.org/estimating-square-foot-coverage-for-products/

Film Thicknesses and Coverage tech sheet: https://www.goldenpaints.com/technicalinfo_filmthickness

Hi Carl,

We have not tested that product, but it looks like it could possibly work. You may need to test to be sure.

Scott,

I am about to try Dibond for the first time. Could I skip the priming and/or gessoing altogether? I prefer a very smooth surface to work on. The Dibond is already bright white. So if I were to sand lightly and then wipe down with alcohol, could I just start in on applying oil paint?

Could I get away with just gessoing the edges with the exposed aluminum and the plastic core?

I work large (60 x 60) so applying layers of gesso is a lot of work, and also adds to the weight.

Thanks.

Hello Catherine,

Yes you could prepare the surface as you say and move on to oils. The sanding went a long way in promoting adhesion of oils and it helps with the acrylics as well if you choose to gesso any part of it. We did some testing in our article Painting with Oils on Non-Porous Substrates. Some Dibond panels have a polyester surface that is paint ready, so you could test on that to see how it works for you and potentially just degrease the surface and get to painting. You could do a scratch test to see if the paints are adhering well to it if you want as well. Hope this helps!

Scott

Hi Scott, Thanks for sharing all this. Have you or anyone else at Golden tried out screen printing on Dibond? I don’t see anything in the above discussions that would suggest otherwise, Thanks,

Leo

Hello Leo,

We haven’t tested screen printing on Dibond, but would expect it to yield good results. The polyester coating is paint receptive, so testing with inks is recommended, but it is a nice smooth surface. If working on raw aluminum, you may needed to prepare the surface with a light scuffing and some isopropyl to clean off any dirt or debris. Give it a shot and let us know how it goes!

Scott

Thanks Scott, will do!

Hello All,

Where do you guys buy your dibond panels? Can’t find any over 10 feet. The panel size I need is 58″ x 124″.

Thanks,

Adam

Hi Adam.

Thanks for your questions. According to the DiBond Product Page, the largest size manufactured is 1500mm x 4050mm, or 59″ x 159″. Your best bet would be to contact the company directly, asking them which of their distributors carries this size. https://www.display.3acomposites.com/dibond/solid-colours/

– Mike at GOLDEN

I have been collage/painting on wood panels and want to switch to Dibond.

Can I use matte or gloss medium (or soft gel?) for the first coat after sanding (as opposed to gesso) and then again for adhering paper to the primed surface? (It seemed that question was answered for aluminum without a polyester coating, while I am asking about priming a polyester coated sheet, specifically, Dibond.)

Thanks.

Hello Heide,

It’s best to follow the same instructions as for raw aluminum and slightly scuff the surface with sandpaper, then degrease with isopropyl alcohol. It should be fine to then use Matte Medium or Soft Gel Gloss directly over Dibond, if you give it a couple of days to dry through. Adding GAC 200, our hardest acrylic medium to the Matte Medium or Soft Gel, will increase durability and improve adhesion of your clear priming layer. It’s best to follow the same instructions as for raw aluminum and slightly scuff the surface with sandpaper, then degrease with isopropyl alcohol.