Linseed oil comes from flax seeds which are harvested from the same flax plant that produces the fibers used to make linen. Artists have been using linseed oil for centuries to make paints, mediums and varnishes. It is widely used today, not only in artist materials, but also for a wide range of industrial applications and as a dietary supplement. Linseed oil dries relatively fast and produces a durable, flexible paint film. The term alkali refined, when used in relation to oils, refers to the way the oil is extracted from the seed and subsequently clarified. This article will describe the alkali refining process and how it produces a high quality oil for use in artist paints and mediums. Williamsburg Handmade Oil Colors uses alkali refined linseed oil in all of our paints, except for our twelve safflower oil colors.

Extraction

All linseed oil starts with flax seeds that are harvested and cleaned. Seeds used to produce alkali refined oil are then optionally toasted or dried, then rolled. Putting the seed through rollers cracks the tough outer shell and turns the seed into a coarse meal. The meal is then heated and hydrated with steam to prepare it for pressing. Adding heat and moisture to the pressing process increases the yield of oil compared to just using pressure to crush the seeds. The drawback from heating and hydrating during pressing, is that the oil contains more plant matter and impurities that have to be removed through refining. After heat pressing, the remaining oil in the meal can be removed through solvent extraction using hexane. The solvent is then separated from the oil through distillation and reclaimed for future use.

Removal of Impurities

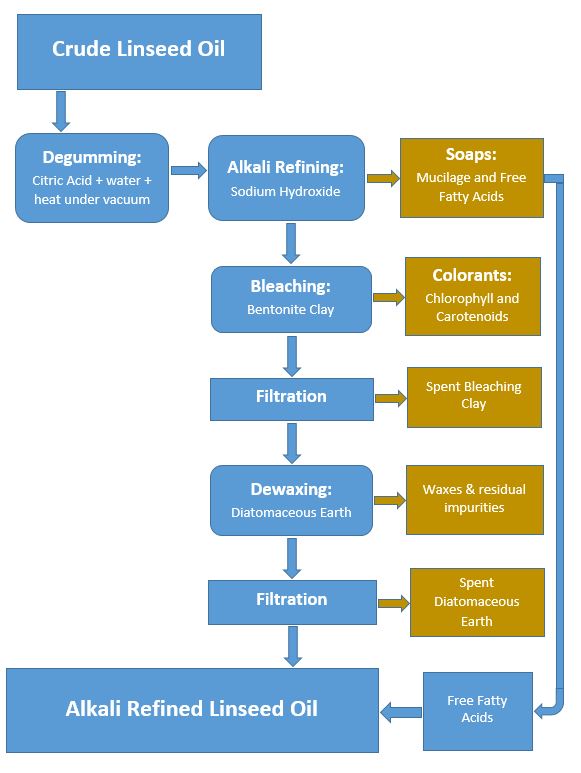

The crude oil then goes through a number of refining processes to remove plant matter, colorants, proteins, waxes, and other impurities to make a clean, stable binder for oil painting and other applications. Acid washing is the first step in this process. Sometimes called degumming, this step helps to remove mucilage, a thick sticky substance, by mixing the oil with water and citric acid under a vacuum at a temperature around 80⁰ C / 180⁰ F (1). These conditions hydrate free fatty acids called phospholipids that are contained within the mucilage. This process links the phospholipids (and the mucilage) to the water and drags them out of the oil in the form of a sludge.

Alkali Refining

An alkaline solution, such as a dilute, aqueous sodium hydroxide, is then added to the tank. This higher PH solution neutralizes the citric acid and forms soaps around the mucilage and remaining free fatty acids. The soaps and the impurities they contain, are then removed through centrifuging. Alkali refining is a very effective method for capturing mucilage and other impurities, but the drawback is that it flushes free fatty acids from the oil. While reducing the number of free fatty acids is beneficial to create a clear, light colored oil that yellows less over time, it is necessary to have a certain amount of free fatty acids in the oil to improve wetting of pigments and flexibility of the paint film. In order to facilitate the proper number of free fatty acids in alkali refined linseed oil, manufacturers recapture and clean the free fatty acids removed during degumming, and then add them back into the oil in varying amounts depending on the desired end product. However, before that step occurs, the oil is bleached and put through filtration.

Bleaching and Final Filtering

Bleaching reduces pigments from the oil such as carotenoids and chlorophyll, in addition to residual “phosphatides, soaps, traces of metals, oxidative products and proteins” (Fediol). These impurities are removed through absorption into a special acid-treated bentonite clay that is mixed into the oil and activated by heat. After it absorbs all these impurities, the spent bentonite clay is then filtered out of the oil and recycled. The almost fully refined oil is then dewaxed either through a low-temperature winterization or by passing it through diatomaceous earth. Diatomaceous earth is a natural substance comprised of the remains of silica-based aquatic organisms. This would be similar to passing the oil through exceedingly fine sand, but the shapes and sizes of the diatomaceous earth particles are variable and therefore more effective at capturing impurities and waxes. The oil is then passed through an advanced filtering system under pressure to remove any residual impurities and spent diatomaceous earth. The final step is to adjust the acid values by adding in free fatty acids to meet the needs of the end user.

Benefits and Uses

Alkali refined linseed oil can be used effectively to make oil paint and oil painting mediums. Traditionally, cold pressed oils have been considered more effective for grinding paint because they have a higher acid number which tends to coat pigments more effectively than oils with lower acid numbers. Fortunately, today’s alkali refined oils are available with a variety of acid numbers to optimize wetting of pigment, drying, and yellowing. Alkali refining linseed oil produces a light, straw-colored oil which is thought to yellow less over time than linseed oils that have not been refined. This is due to the reduced number of free fatty acids and plant matter in the oil. Alkali refined oils are also consistent in their acid numbers, color, and cleanliness, making them a reliable choice for manufacturers. As dedicated as we are to alkali-refined linseed oil, we continue to test a variety of oils for dry time, film integrity and color stability. In addition, we have also explored more traditional refining methods since these might present advantages or qualities often overlooked or lost in the drive for more efficient, industrial processes. Ultimately, Williamsburg Handmade Oil Colors is committed to exploring materials guided by science, research, and the insights from the conservation community. So, if another oil or method looks promising, we would not hesitate to consider that option. But, for now at least, alkali refined linseed oil remains the best choice.

If you have any questions or comments about this article or any other paint related topic, please feel free to contact our Materials Application Department at [email protected] or by calling 800-959-6543.

References:

- “Flaxseed (linum Usitatissimum L.) Oil Processing and Selected Products: A Review”, Trends in Food Science & Technology, Volume 43, issue 2, June 2015, pp. 162-177

http://www.sciencedirect.com/science/article/pii/S0924224415000473 - Fediol, Chemical Refining Flow Chart and Information: http://www.fediol.be/web/chemical+refining/1011306087/list1187970119/f1.html

- Fediol, Oilseed Crushing Flow Chart and Information: http://www.fediol.eu/web/oilseeds+crushing/1011306087/list1187970116/f1.html

- Fediol, Physical Refining Flow Chart and Information: http://www.fediol.be/web/physical+refining/1011306087/list1187970120/f1.html

- MITRA- Materials Information and Technical Resources for Artists/Resources/ Mediums and additives for painting: https://www.artcons.udel.edu/mitra/Documents/MITRA_Mediums_and_Additives.pdf

About Greg Watson

View all posts by Greg Watson -->Subscribe

Subscribe to the newsletter today!

Thanks for this article. You made it so simple, even I could understand it. 🙂

Hi Chris,

You are very welcome! Glad you enjoyed it – thanks for letting us know.

Greg

I never knew the process was so complex and had so many steps,

What’s involved to produce Cold Pressed Linseed oil?

Thanks

Hello Mark,

We learn a lot from researching these articles too, including how complicated industrial processes can be! Another interesting point that wasn’t mentioned in the article, is that the artist materials industry uses only a small fraction of the oils produced for food, the coatings industry or for other industrial uses.

Regarding cold pressed oil, it also goes through a number of steps without the use of chemicals or heat. The seeds and oil must be kept below around 100 degrees F in order to be classified as cold pressed. The seed is pressed without steam which produces less oil with less impurities. Because pressure creates heat, the presses can be cooled. The oil is captured under a blanket of nitrogen to keep the oil fresh and so it does not oxidize. The oil can be washed with water and/or clay, filtered and centrifuged. They might also winterize the oil, which cools it to the point when the waxes in the oil solidify and drop out.

Thanks!

I agree that you have broken down a very complex process so a non chemist can understand. It really made me understand the difference between this product and cold pressed oil and the advantages in preparing paint and using as an additive. Thank you. I am sharing this with my students. Bravo

Hello Kristine,

Thank you for your comment and for sharing this article with your students! We are glad you found it helpful!

Best Wishes,

Greg

Linseed oil has been recommended to stabilize plywood woodblocks for Japanese style carving and printing. One source mentions “activated linseed oil.” Is that simply boiled linseed oil? Further can you comment on drying times? One source says it takes several days and another says about a single day. Thanks very much.

Hello Jawed,

Unfortunately, we do not have specific information about different presses and the pressure or temperature they produce. There are standard requirements for keeping the seed under a certain temperature (~100F) in order to label the oil product “cold pressed”, but for heat and steam pressing, the heat and pressure used to extract the oil seem to be determined by the type of press and the desired end use for the extracted oil. Perhaps you can contact a seed press manufacturer an inquire about the specs of their machines.

We wish you the best in your research.

Greg

Sir.. what is the process for only break free the linseed oil.. is the alkali oil.and break free oil same?

Hello Sir,

We are not sure if these terms can be used interchangeably. It appears break-free oil has been cleaned to some extent, perhaps with an acidic solution only. This is to remove the “break” or gums, also called mucilage, from the oil. Removing these impurities allows the oil to be heated without “breaking” or becoming cloudy and clotted. Oils that are heated in this way are typically used for varnishes. Alkali refined linseed oil has likely been through a more vigorous cleaning process than break-free oil.

We hope this helps.

Greg Watson

Hi we are a paint manufacturing company & for testing of incoming pigments & extenders we need acid refined linseed oil with an acid value of 5-7 mg KOH/gm of sample. This test is as per ISO 787 specification. Can you please suggest?

Hello John,

There are a number of larger linseed oil manufacturers who provide oils with varying acid values. We do not disclose our manufacturer, but quick internet search should turn up several results.

Take care,

Greg

Hi, for refined linseed oil since it removes acid, will it still form strong film as cold pressed linseed oil?

Hello Tu,

The free-fatty acids that are removed during alkali refining are not part of the triglyceride structure which primarily forms the film. Free fatty acids are washed out of the oil as a soap and then collected, cleaned and replaced back into the oil at varying levels. The levels depend on the needs of the end user. Free fatty acids can help wet pigments, so it is thought cold pressed oil is beneficial for that purpose. Otherwise, it seems from our research and in-house testing that Alkali Refined oil and cold-pressed are on par in terms of film formation and long term durability. Plus, the longevity of an oil paint layer is so dependent on the pigments used, that is difficult to disconnect the two in any real life study.

Please get in touch with any additional questions. [email protected]

Greg

Could a neutral or low acid oil be used to size canvas. I don’t like using plastic or animal glue as a size.

Hello Andrew,

Not sure any of the drying oils wouldn’t have some level of acidity. Unfortunately, cannot think of any alternatives to hide glues, acrylics or PVAs for sizing fabrics. You could try a polyester fabric, which wouldn’t degrade with oil contact. But again, you would be using synthetic materials.

We will certainly keep our eye out for effective alternatives and let you know when we find something!

Take care

Greg

HI Warren,

sorry for the delay in response…thanks for your comment. We have not tested starches as sizing. But an interesting idea and perhaps something to be tested.

Best Wishes,

Greg

Hello

Williamsburg Cold pressed linseed oil is described on the web as „Less processed than alkali-refined.“ Does that „Less processed“ mean, that it is processed to certain degree, but not as much as alkali refined?

For example Schmincke offers cold pressed linseed oil, described as „Natural, mucilage-free linseed oil from first pressing,“ (https://www.schmincke.de/en/products/mediums/oil-mediums/linseed-oil-cold-pressed.html) and Kremer pigmente offers cold pressed linseed oil from Sweden, described as „Linseed oil from Sweden, cold-pressed and filtered“ (https://www.kremer-pigmente.com/elements/resources/products/files/73020-73600_Oils.pdf). When I asked Kremer pigmente about the „filtered“ part, I was told that it is cold pressed and cleansed from mucilage by letting it settle, but not treated any further.

Is Williamsburg cold pressed linseed also at least filtered, i.e. without mucilage?

By the way, pity that Williamsburg doesn’t make Sun thickened linseed oil any more (although I know, that there are few other sources).

Regards

Ivan

Hi Ivan,

Oil manufacturers can be somewhat reluctant to detail their process point by point. What we have discussed with our provider is that cold pressed oil is extracted without heat or solvent and then winterized and filtered. Winterization and filtering removes waxes and then colorants, plant matter and mucilage respectively. Sorry about the sun thickened oil. Perhaps you can make your own during the summer months!

Take care,

Greg

Thank you so much for a totally comprehensible article. I thoroughly enjoyed reading it. If I was to set about making paints using a three roll mill, is this alkali-refined oil the best choice? If not, what type of linseed oil would you recommend? If I was going to mix in some walnut oil, which kind of walnut oil do you recommend? If there are different kinds. Thanks so much for writing articles like this.

Warmly, David

Hi David,

Thank you for your comment. Yes, you can use Williamsburg alkali refined linseed oil to make your oil colors. That is what we use for our paints. The cold-pressed oil will work also. As for walnut oil, you may be able to find refined walnut oil in the art supply shops, but if not, you can try Kremer Pigments. They have a refined Walnut oil: https://shop.kremerpigments.com/us/shop/mediums-binders-glues/73500-walnut-oil-refined.html

The walnut oil in food stores may contain anti-oxidants to help with freshness. While this shouldn’t harm the paint, it may slow drying of your oil colors and might not be preferable.

Hope it goes well!

Greg

Hi, this is helpful, thanks. What exactly is the difference between boiled linseed oil and linseed stand oil?

Many thanks

HI Treg,

Boiled oil that is found in hardware and wood supply stores is a raw linseed oil that contains driers to speed the curing. It may be heated to thicken its viscosity, likely in the presence of oxygen, which also helps speed drying. Stand oil is heated to 300C without oxygen. It is polymerized and thickened, but the thickening process does not create crosslinks in the oil therefore does not help speed dry time. Stand oil will yellow significantly less than boiled oils.

Hope this helps!

Greg