What could be more important to the longevity of a painting than the proper selection and preparation of the substrate you are working on? Having a vested interest in the success of artists using our products, we want to highlight some of the concerns coming from the field of conservation regarding surface checking and the use of plywood as a fine-art material. We will offer some possible explanations for this phenomenon and some suggestions to help mitigate the effect of surface checking. First, however, we will start with some background on how plywood is manufactured to provide a little context.

Plywood and The Generation of Surface Checking

When referring to plywood, we mean engineered wood products constructed by cross-laminating and adhering veneer or thin slices of wood together under heat with pressure using strong adhesives. The main advantage of this construction, at least for painting supports, is its dimensional stability and resistance to movement when exposed to changes in moisture and humidity. The cross-laminated structure imposes a ‘forced stability’, in a sense, and while this results in desirable structural attributes, it is also the cause of many of the concerns surrounding plywood.

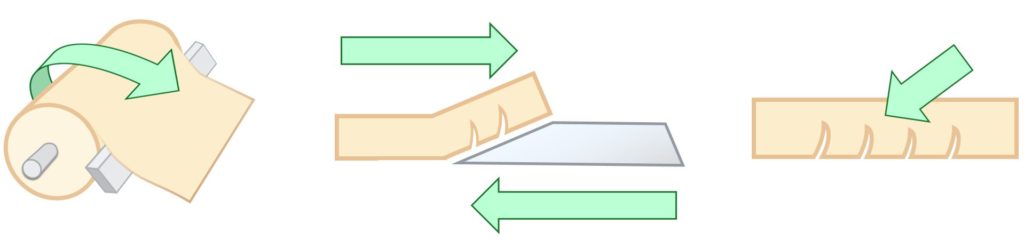

Most plywood veneer is created through rotary lathe cutting, a process where a log is softened by either boiling or steaming and then is fixed and balanced on a lathe where thin slices of veneer are peeled off in a spiral by a fixed skimming knife as the log rotates. As the knife enters the wood and separates the veneer from the log, it is bent tangentially under tremendous shearing forces. The stresses resulting from this can exceed the strength of the wood, causing failure in the form of lathe checks. The term ‘checks’, when talking about wood, refers to cracks or splits in the wood’s surface. Any stresses from this process are then retained in the plywood as the veneer is laid flat, bonded together and restrained with an adhesive.

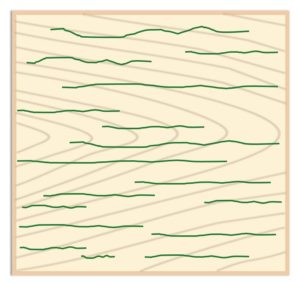

The adhesives themselves offer increased resistance to moisture resulting in improved dimensional stability, but wood is still hygroscopic (or ‘water loving’) and wants to exchange moisture with its environment. (Minor, M. 1993) As these fluctuations occur, or are introduced as a byproduct of water-based paints or grounds, it causes swelling and shrinking in the restrained wood. This fluctuation can create enough tension to overcome the resistance of the plywood to splitting, known as its tensile strength. As the natural tendency for wood is to find the easiest method to relieve this stress, these lathe checks, being a weakness in the veneer, may open up and cause larger surface checks running along the grain of the wood. If the extent of the checking overcomes the flexibility of the ground layers, they may become visible as small cracks and telegraph through subsequent layers of paint.

The Bad

Unfortunately, there is not much that can be done to patch up checking once it occurs. There is a risk that any attempt to fill these cracks could add additional stress to the wood. (Minor, M. 1993) Additional layers of paint intended to cover the cracking would also be susceptible to future cracking and there is no evidence in our research that finishes will have an impact on the formation of surface checking aside from perhaps slowing it down. (Leavingood, S., Funck, J. W., Reeb, J. E., 2011) Attempts to further restrain the plywood with the addition of cradling could retain even more stress in the wood thereby exacerbating risks. As checking is tied to an intrinsic process in the manufacturing of all plywood, even high grades of plywood could exhibit surface checking.

What are Your Options?

While plywood is far from perfect, it is a staple for many artists and will continue to be long after this or other articles are published. There are some measures that can be taken to mitigate the effect of surface checking that have some support in the field of conservation. One would be to adhere canvas or paper to a panel facing. This can help reduce evidence of grain and the effect of checking on paint layers by providing an intermediary between the painting and the substrate. We often recommend using Medium Density Overlay (MDO), which is an exterior plywood with a resin impregnated fiber overlay that functions similarly. There is some research suggesting that the adhesive used in the plywood may also play an integral role in the development of surface checking with water resistant Urea Formaldehyde (UF) adhesives being more susceptible. (Tremblay, C. Bouffard, J. F. 2012) The phenolic resin that is used to saturate the overlay in MDO and bond the veneer is a water proof adhesive that offers better moisture resistance, which may help reduce the impact of the environment or water-based paints and grounds on raising a panel’s moisture content. There can also be measures made to stabilize or control the relative humidity of studio conditions, thereby reducing fluctuations that could lead to checking. Even choosing higher grades of plywood with less voids, and of less porous wood species can create less opportunities for lathe checks to travel through to the surface of the veneer. If having a rigid support is what is most important, there are many engineered wood alternatives, metal supports and various acrylic sheeting options that could be used as well. Here is some additional information on MDO and a short video showing a process for adhering paper to panel:

Medium Density Overlay

Adhering Paper to Panel

Over time, as our research advances and we develop a greater dialogue with artists and conservators, we will often need to reevaluate past recommendations in light of new evidence. This is one such case and, as we learn and update our advice, we want to share that knowledge in the hopes that it may serve to inform artists of potential risks to the longevity of their works. If you have any questions or comments about this article or any other paint related topic, please feel free to contact our Materials Application Department at [email protected] or by calling 800-959-6543.

References:

- College of Forestry, Oregon State University. (2018) Maple Veneer Checking Research. Retrieved from: http://owic.oregonstate.edu/maple-veneer Accessed on March 11, 2019.

- Forbes, C. (1997) Understanding and Minimizing Veneer Checking on Furniture Panels. NC State Extension Publications. Accessed on March 11, 2019.

- Klim, Susan (1990). Composite Wood Materials in Twentieth Century Furniture. The Conservation Information Network. Retrieved at http://www.wag-aic.org/1990/WAG_90_klim.pdf

- Leavingood, S., Funck , J. W., Reeb, J. E. (2011) A Note on Face Veneer Checking in Maple Plywood, International Wood Products Journal. 2:@, 120123.http://dx.doi.org/10.1179/2042645311Y.0000000010

- Minor, M. (1993) The Nature and Origin of Surface Veneer Checking in Plywood. Department of Objects Conservation, The Metropolitan Museum of Art, New York, N.Y.

- Tremblay, C. Bouffard, J. F. (2012) Study on the Issue of Veneer Cracking in the Kitchen Cabinet and Furniture Industry. Natural Resources Canada, Forestry Canada and Economic Development Canada. Value to Wood Report FPI-11-01. Project No. 201005269.

About Scott Fischer

View all posts by Scott Fischer -->Subscribe

Subscribe to the newsletter today!

In my ten year experience as a painter I’ve almost abandoned wood for portrait sized paintings, it always cracks. In the past quarter sawn oak was used and if you can afford it then it still may be a great solution to avoid cracking. For larger paintings I use canvas with all its problems :-(. I’ve replaced the wood with aluminium panels, I glue them to marine ply, I find this surface, easy to prepare, super smooth to paint on and really stable, I believe from my research that it is archival. I would never have believed it until I tried it and I recommend it to anyone looking to try something to solve the problem of wanting an archival surface.

Hello Purcell,

Thank you for your comments and suggestions! Solid wood does release stress more readily than plywood, but this also correlates to greater dimensional movement. As you suggest, the use of aluminum panels can be a great alternative to wood if you are interested in having a stable rigid support. For those interested, information on preparing metal panels can be found here: Painting on Metal an Introduction

We hope this is helpful and if you have more questions, feel free to contact us at [email protected].

Thanks Scott, this is was very informative, and also disconcerting. I’ve been using plywood panels for years, thinking I’ve got all my bases covered. I had always assumed that two generous coatings of GAC100, followed by Gesso, would shield the plywood from environmental stresses… But your research casts doubt on plywood’s structural integrity. I live in a country where our summers are scorching dry, and our winters are soaking wet. I’m guessing that these fluctuations will only aggravate the plywood’s habit of checking. I guess it’s time to bring on the aluminium panels….

Hello Alex,

As you mentioned in your comment, fluctuations in the relative humidity of the environment plays a key role in whether or not the plywood will develop surface checks. If the painting remained within a particular relative humidity range for its lifespan, it may not develop surface checking.

We do want to mention that acrylics or even varnishes do not act as good vapor barriers. While your method of preparation may help block Support Induced Discoloration (SID) or even block oil penetration into the plywood, the piece will still be very much influenced by its environment.

We hope this is helpful and if you have more questions, feel free to contact us at [email protected].

Sorry, one last question Scott… After reading your newsletter, it seems preferable to attach a more stable support to plywood than painting directly on to the wooden panel. If I wanted to glue aluminium panels on to plywood, which Golden product would you recommend? Would GAC 100 be strong enough? I’m guessing that the smooth, non-porous surface of the metal might cause adhesion problems?

Hello Alex,

If you wanted to adhere an aluminum panel to plywood, we would recommend using a Construction Adhesive. There are many options available at your local hardware store, just make sure the one you choose is compatible with both aluminum and wood. We have not tested using acrylic to bond metal to wood, and something like GAC 100 or even a heavier Gel may not be strong enough. Due to the lack of porosity of the metal, it may also take a long time to fully dry as acrylic dry through evaporation. Using an acrylic gel, for example, would also require treating the glue side of the aluminum by scuffing and de-greasing first and depending upon the type of aluminum panel, it may require a Direct to Metal Primer (DTM). This is the same surface preparation we recommend for painting on Aluminum with acrylics. More information can be found here: Painting on Metal an Introduction

Additionally, if you are getting a nice rigid support from the aluminum panel, it may not be necessary to further back this support with plywood. The metal itself would be dimensionally stable. If doing so is important to your process, then the construction adhesive may be the way to go.

We hope this is helpful and if you have more questions, feel free to contact us at [email protected]

I have a question, how to stain already glued veneer? glue spots are all around…. Thank you!

Hi Hannah,….It may be very difficult to stain any areas where wood glue has soaked into the wood as it will tend to make the wood non- porous. You could try sanding the glue spots to expose porous wood. And here is a link to information about staining wood with our products: https://goldenpaints.com/technicalinfo/technicalinfo_woodstain